Digital technology for industrial sustainability and optimization

Get deep insight into process performance and optimize your operations in real-time for lower emissions and improved operating margins.

Digital technology for industrial sustainability and optimization

Get deep insight into process performance and optimize your operations in real-time for lower emissions and improved operating margins.

Capacity increase (%)

Energy savings (%)

Emissions reduction (%)

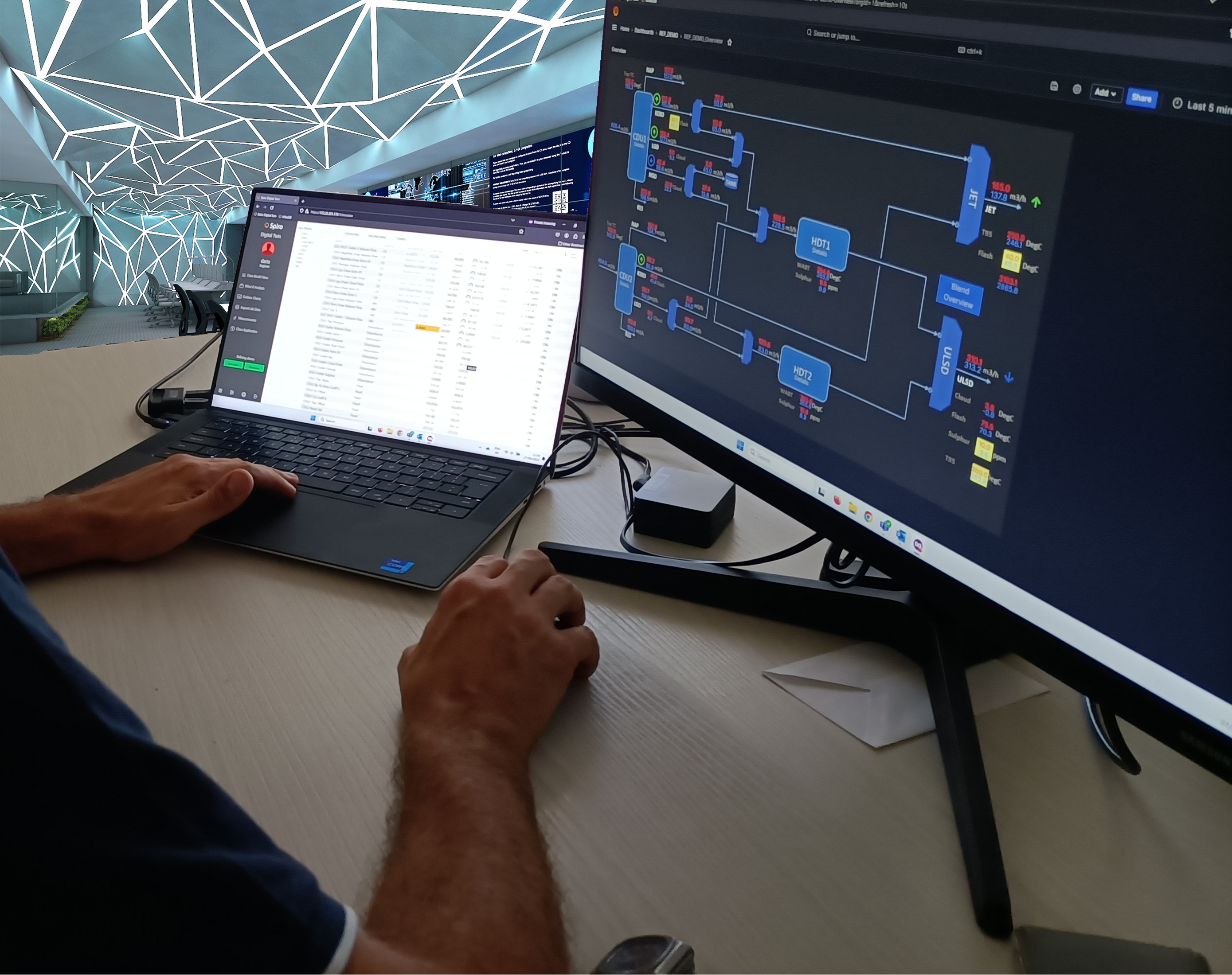

Spiro augments real-time industrial optimization and advanced control with AI-driven solutions, empowering plant operators to improve efficiency, lower emissions, and reach operational excellence.

Spiro augments real-time industrial optimization and advanced control with AI-driven solutions, empowering plant operators to improve efficiency, lower emissions, and reach operational excellence.

“A proficient control engineer can squeeze more production out of limited plant equipment and contribute more to reducing operating costs than almost any other individual in the plant.” — Greg Shinskey.

At Spiro, we’re not just another AI company. We are a team of skilled practitioners with decades of hands-on experience in process control, advanced process control, and industrial process optimization. We understand the complexities of process plants—how to control them and manage their limitations and interactions.

We recognize the transformative power of AI in process plant operations. We also view AI as one important tool among others, working alongside well-tuned regulatory control, model predictive control and non-linear rigorous process models. In the right hands, these tools can drive exceptional results, empowering process operators to accelerate digital transformation and achieve operational excellence.

“A proficient control engineer can squeeze more production out of limited plant equipment and contribute more to reducing operating costs than almost any other individual in the plant.” — Greg Shinskey.

At Spiro, we’re not just another AI company. We are a team of skilled practitioners with decades of hands-on experience in process control, advanced process control, and industrial process optimization. We understand the complexities of process plants—how to control them and manage their limitations and interactions.

We recognize the transformative power of AI in process plant operations. We also view AI as one important tool among others, working alongside well-tuned regulatory control, model predictive control and non-linear rigorous process models. In the right hands, these tools can drive exceptional results, empowering process operators to accelerate digital transformation and achieve operational excellence.

Process control tools that scale with your business

We match vast industrial control experience and knowledge of mathematics with a portfolio of AI, data-driven analytics, advanced control, and real-time optimization applications.

Process control tools that scale with your business

We match vast industrial control experience and knowledge of mathematics with a portfolio of AI, data-driven analytics, advanced control, and real-time optimization applications.

Expertise

Our Principal Consultants bring decades of expertise in industrial control. We are technology-agnostic, allowing us to seamlessly integrate and collaborate with various applications and platforms. Our development team comes from diverse backgrounds, including Chemical and Mechanical Engineering and Computer Science, ensuring that we deliver practical, scalable solutions for industrial applications.

Leading technology

Our Digital Twin and Optimization applications operate in real-time, leveraging rigorous thermodynamic models and data-driven AI. Our embedded MPC algorithms are capable of millisecond execution. With intuitive web-based user interfaces and integrated dashboarding solutions, all our products are designed as IIoT/Industry 4.0 solutions. We leverage AI and machine learning to train process models, reducing run-time requirements and enhancing overall performance.

Agile methodology

We prioritize ongoing communication with our clients, promoting close collaboration throughout the project. By using an Agile approach for all of our projects, we can quickly adapt to change requests and feedback as the project progresses. Early application allows us to gather feedback sooner, reducing the time and costs typically associated with lengthy iterations during the commissioning phase.

Sustainability and Digital Transformation

As technology advances, Spiro is empowering organizations to adopt a data-driven culture. We are committed to developing innovative products and processes that reduce carbon emissions, conserve resources, and extend operational lifespan, all with the goal of fostering a cleaner, safer, and more sustainable future for everyone.

Industries

Industries

Upstream

NGL & Gas Processing

Refining

Olefins

Chemicals

Food & Beverages

Mining, Minerals & Metals

Power & Utilities

NEXT STEPS

Upgrade your plant in three quick steps

Upgrade your plant in three quick steps

Real-time visibility

Understand what’s happening now.

Operational awareness

Make data driven adjustments on the fly.

Intuitive analytics

Continuously improve for long term growth.

Contact Us

Let us know how we can help!

Email:

info@spirocontrol.com

Or schedule a meeting

Use the calendar below to schedule a meeting with a member of our team.

Or schedule a meeting

Use the calendar below to schedule a meeting with a member of our team.

Thornton Science Park, Cheshire, CH2 4NU, UK

info@spirocontrol.com

Solutions

Products & Services

Industries

News & Updates

Company

Contact