Spiro Digital Twin

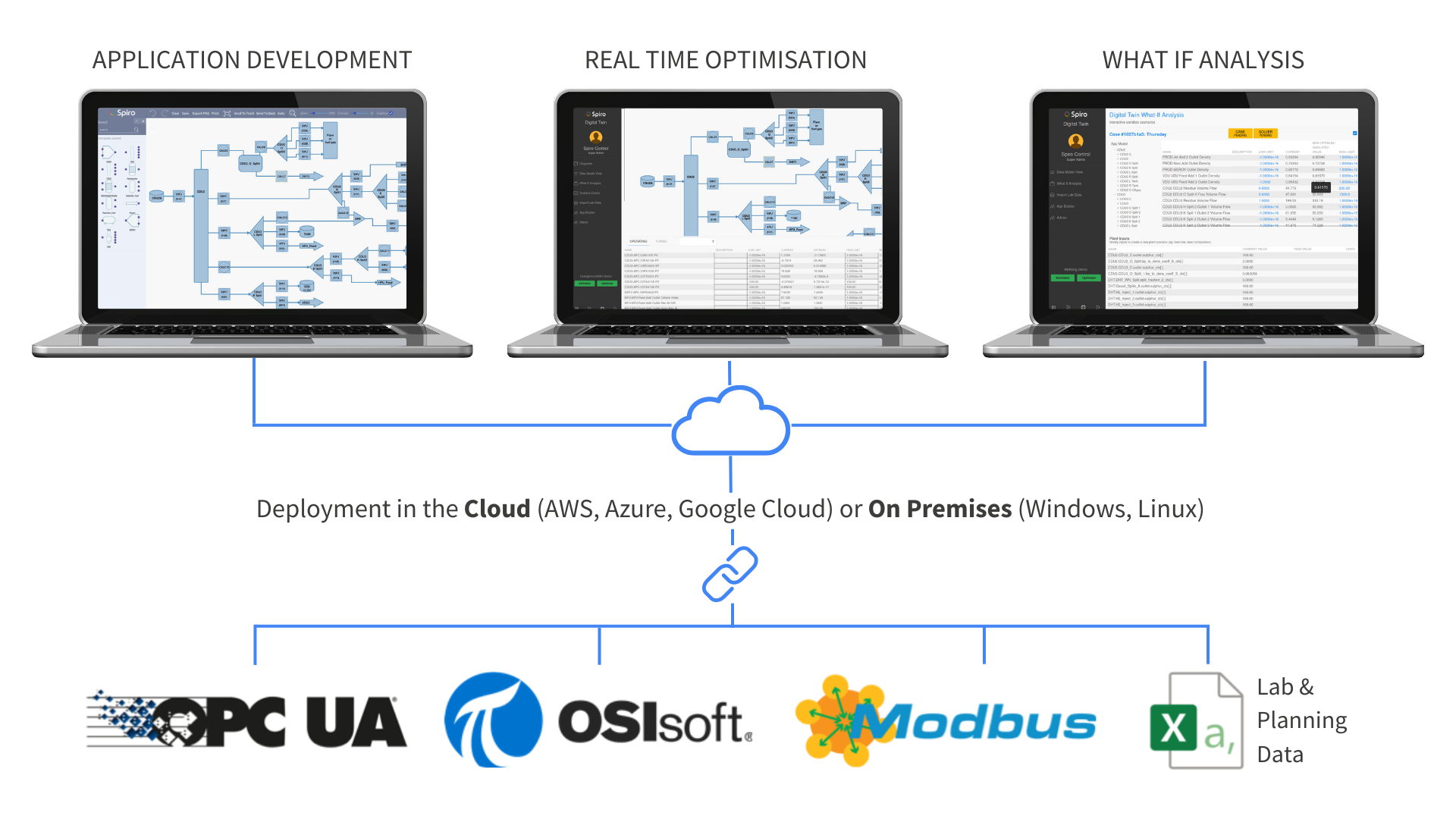

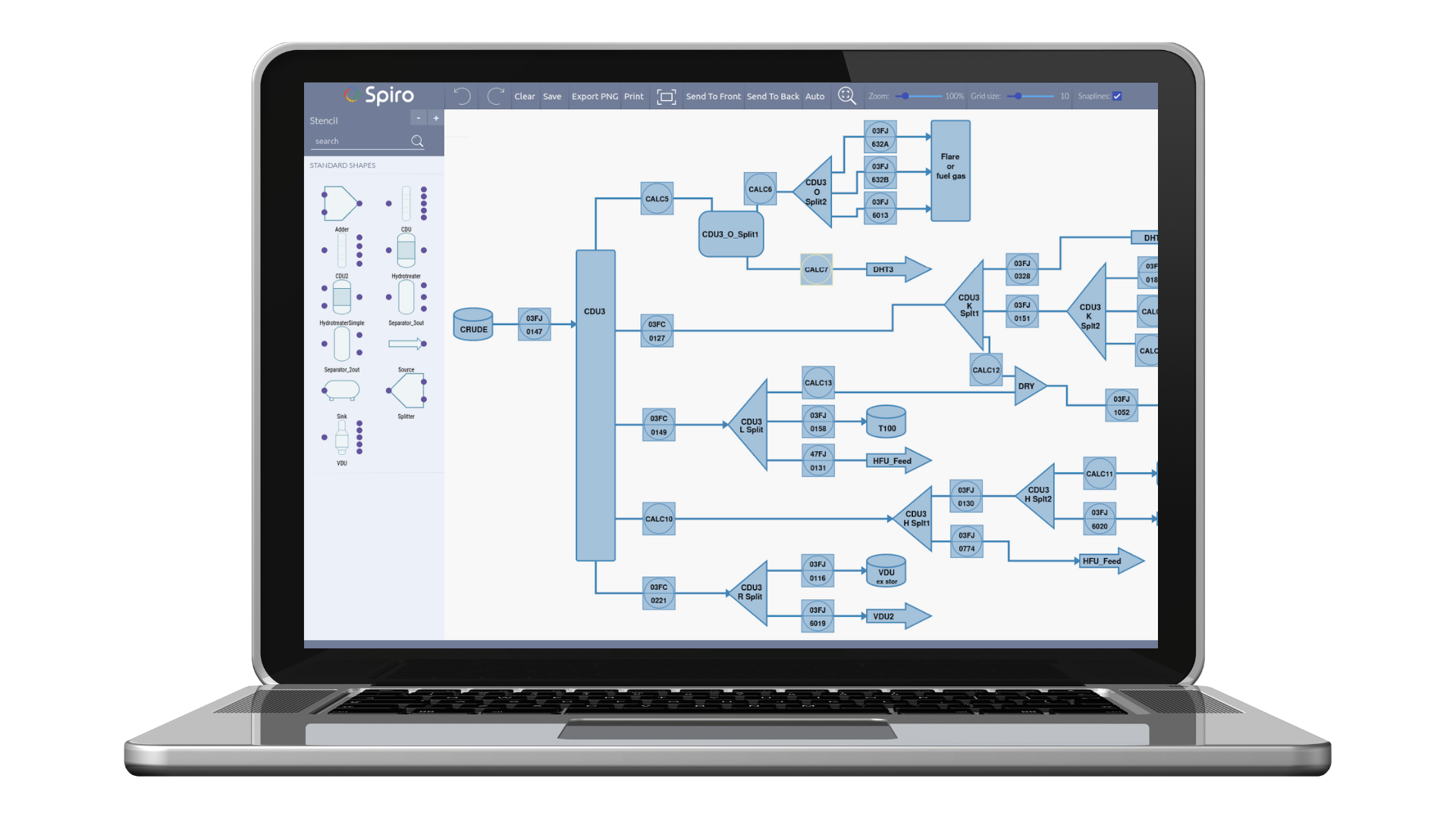

Spiro Digital Twin provides deep insight into process performance, allowing operators to optimise their operations in real-time. The result is lower emissions and improved operating margins.

Spiro Digital Twin

Spiro Digital Twin provides deep insight into process performance, allowing operators to optimise their operations in real-time. The result is lower emissions and improved operating margins.

Meeting the needs of process plant operators

We help process operators, planners and supervisors to make accurate and consistent decisions. The Spiro Digital Twin blends physics- and data-driven twins to support optimisation throughout the product’s lifecycle. We take a complete, open, and flexible approach that enables your digital transformation vision on your terms.

Meeting the needs of process plant operators

We help process operators, planners and supervisors to make accurate and consistent decisions. The Spiro Digital Twin blends physics- and data-driven twins to support optimisation throughout the product’s lifecycle. We take a complete, open, and flexible approach that enables your digital transformation vision on your terms.

WHY A DIGITAL TWIN?

Digital Twin meets the needs of process plant operators

Operating objectives:

- Maintain safe and reliable operation

- Minimise environmental emissions and flaring

- Meet production targets

- Reduce losses

- Maintain product quality and yields

- Optimise energy and resource use efficiency

Digital Twin meets the needs of process plant operators

Operating objectives:

- Maintain safe and reliable operation

- Minimise environmental emissions and flaring

- Meet production targets

- Reduce losses

- Maintain product quality and yields

- Optimise energy and resource use efficiency

Daily challenges:

- Changing feedstock availability and price

- Changing consumer demand due to planned or unplanned outages

- Changing process equipment condition

- Limited availability of equipment due to maintenance or reliability

Daily challenges:

- Changing feedstock availability and price

- Changing consumer demand due to planned or unplanned outages

- Changing process equipment condition

- Limited availability of equipment due to maintenance or reliability

USE CASE

A shift manager on a petrochemical process uses a digital twin to make timely and correct decisions to manage production and maximize profits.

On starting a new shift, she needs to make a rapid assessment, not just of how her plant is operating but also of the state of any connected processes and storage facilities.

The digital twin can anticipate the impact of impending feedstock or inventory changes and advise on optimal adjustments that need to be made during the shift. Even the weather forecast might influence these decisions and need to be included in the model.

By checking dashboards that use derived and validated data from the digital twin, she can assess overall process operation by checking key performance indicators such as intrinsic energy consumption and net carbon emissions. Data analysis can be used to anticipate planned equipment outages and to update maintenance plans.

A shift manager on a petrochemical process uses a digital twin to make timely and correct decisions to manage production and maximize profits.

On starting a new shift, she needs to make a rapid assessment, not just of how her plant is operating but also of the state of any connected processes and storage facilities.

The digital twin can anticipate the impact of impending feedstock or inventory changes and advise on optimal adjustments that need to be made during the shift. Even the weather forecast might influence these decisions and need to be included in the model.

By checking dashboards that use derived and validated data from the digital twin, she can assess overall process operation by checking key performance indicators such as intrinsic energy consumption and net carbon emissions. Data analysis can be used to anticipate planned equipment outages and to update maintenance plans.

Why should you power digital twins with Spiro Control?

Why should you power digital twins with Spiro Control?

Provides an accurate model that reflects real process conditions and molecular components.

Uses real-time data to ensure that decisions reflect the current process state and the latest planning information.

Ensures that all plant constraints and operating objectives are accounted for.

Provides what-if tools to evaluate future operating scenarios and to audit past events for improved understanding and knowledge.

Allows users to save and share what-if cases.

Provides dashboards to monitor and benchmark current performance.

Provides time series trends to evaluate past scenarios.

A simple tool that is accessible to all stakeholders for improved decision-making.

Arkema deployed Spiro’s technology as part of our commitment to the Paris Climate Agreement. We achieved sufficient steam savings to decommission a site boiler. The project delivered significant benefits through reduced energy costs and CO2 emissions.

Jerome Berjouan

Process Control Specialist, Arkema

CONTACT SALES

Talk to an expert

Talk to an expert

Spiro Control reps aren’t just sales guys. Our team features extremely knowledgable people with experience in refining and chemicals who can help you formulate a custom solution for your company.

Schedule a meeting with a member of our team, give us a call at +44 1244 568 940, or chat with our team – whichever contact option you prefer, we’re here to help.

Spiro Control reps aren’t just sales guys. Our team features extremely knowledgable people with experience in refining and chemicals who can help you formulate a custom solution for your company.

Schedule a meeting with a member of our team, give us a call at +44 1244 568 940, or chat with our team – whichever contact option you prefer, we’re here to help.

Or schedule a live demo

Use the calendar below to schedule a meeting with a member of our team.

Or schedule a live demo

Use the calendar below to schedule a meeting with a member of our team.

Solutions

Products & Services

Use Cases

News & Updates

Company

Contact