Spiro MPC

Powerful Embedded Model Predictive Control Out of the Box.

Spiro MPC

Powerful Embedded Model Predictive Control Out of the Box.

Industry Standard IEC-61131-3 Control with CODESYS

Communications: MODBUS, Ethernet IP, OPC UA, PROFINET

Graphical & Structured Languages for Custom Programs

Industry 4.0: OPC UA Pub/Sub, MQTT Client

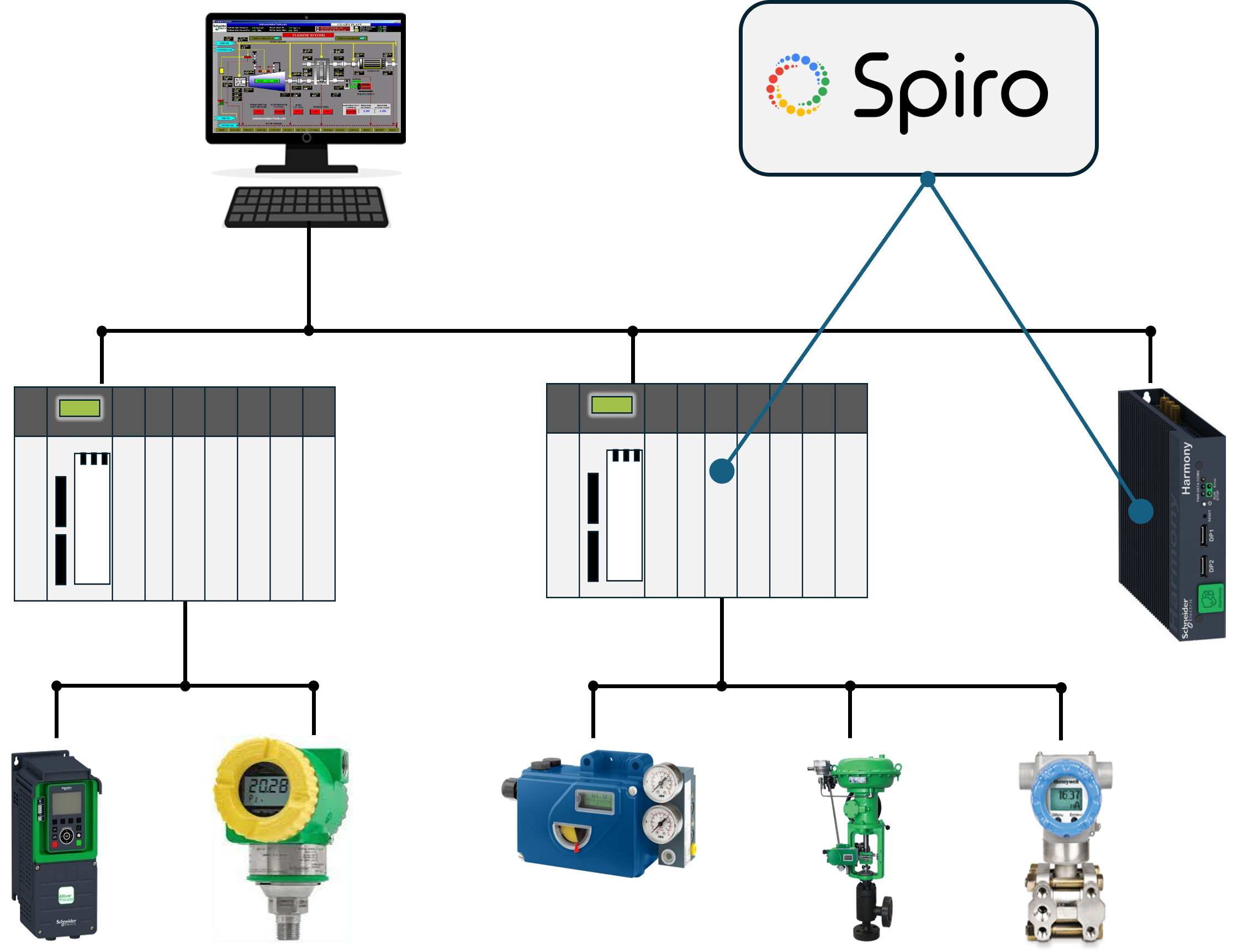

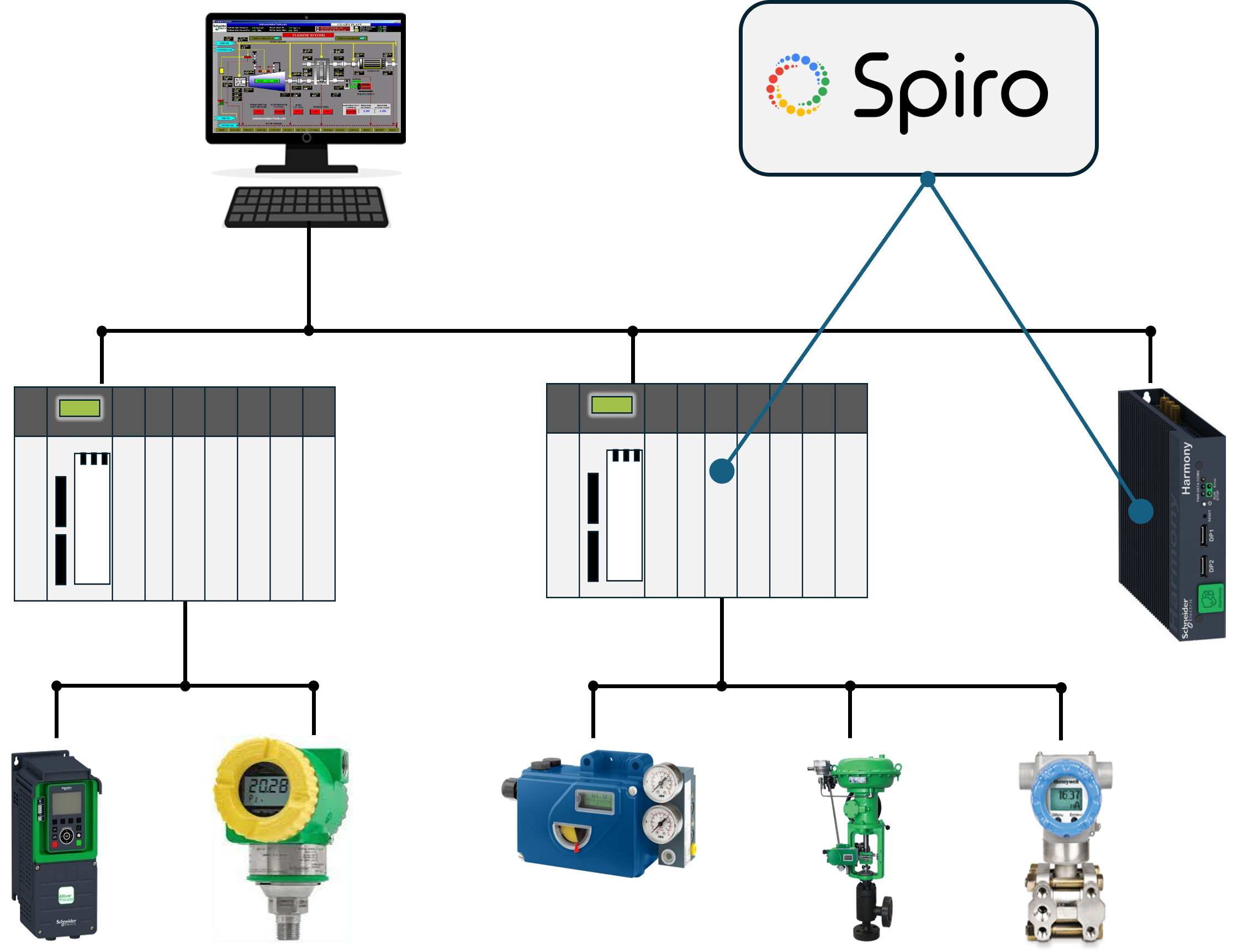

Spiro Edge Control

Spiro MPC is designed for ease of use right out of the box. You don’t need to be an APC expert—our sophisticated algorithms ensure the controller performs efficiently with the default tuning parameters. Plus, there’s no need for costly servers or cloud services. Spiro MPC can be deployed on a PLC backplane or a low-cost edge device, making it highly accessible.

By putting advanced process control directly in the hands of your instrument technicians, Spiro MPC combines simplicity with powerful performance. The results? Optimized operations that boost margins and reduce emissions. With a typical installation, you can expect a return on investment in under three months.

Spiro MPC deploys directly on a PLC device or PLC network providing a simple, robust, cost-effective solution that is easy to install and maintain.

Low Latency and Fast Execution. Cost-Effective Implementation. Reliability and Robustness. Enhanced Cyber Security.

Some Supported Devices

Modicon M580, Harmony Edge Box

Allen-Bradley ControlLogix

Hyperconverged Edge Controller

PLCnext Controller

Industrial Edge Computers

Docker Container

Increase Production by Up to 5%

Reduce Energy Use by 10%

Lower Emmissions by 5%

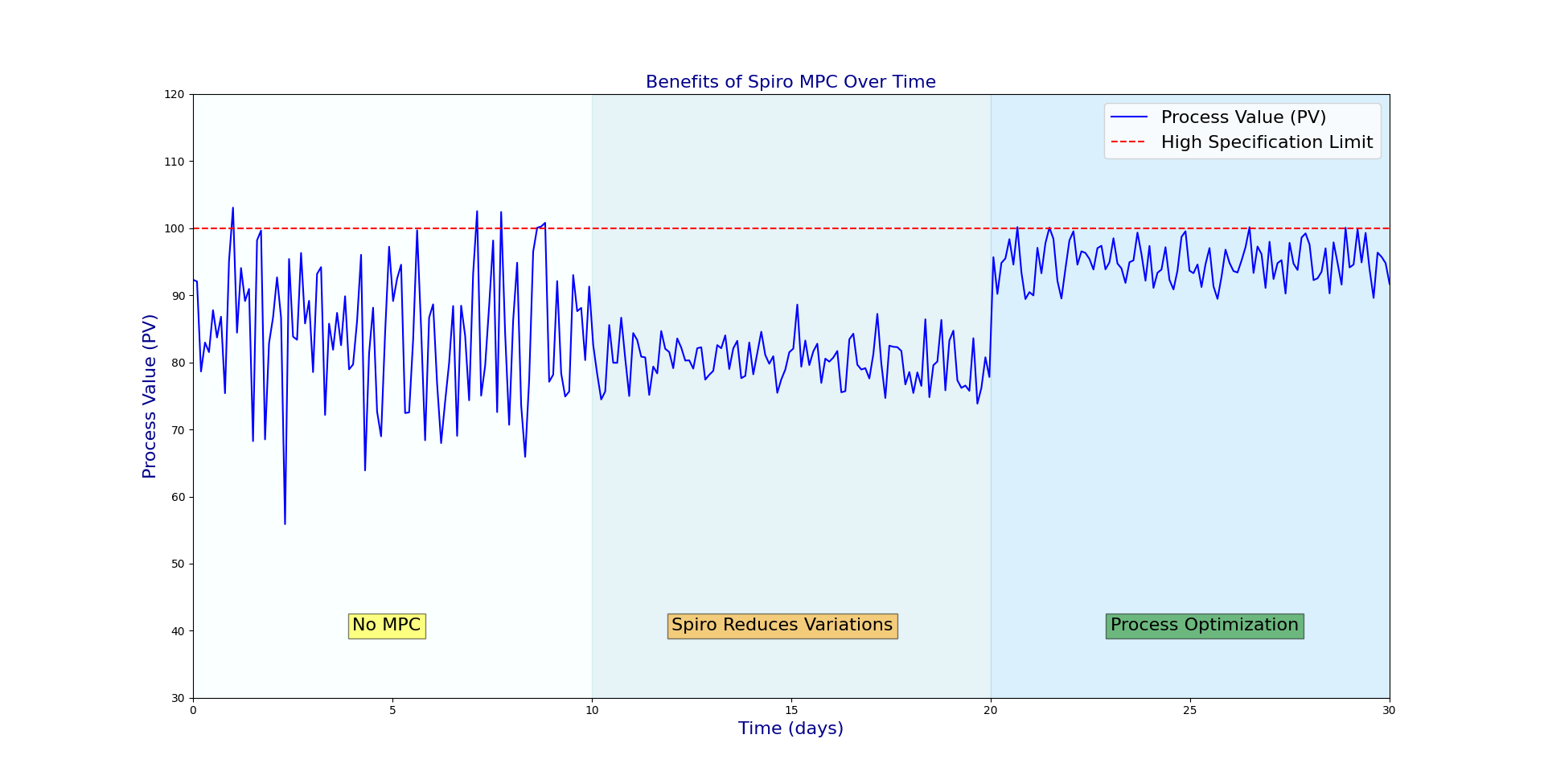

Lower Your Process Variability and Maximize Your Profits

WHAT IS SPIRO MPC?

Spiro MPC employs highly efficient state space control algorithms which achieve millisecond execution. By continuously monitoring and analysing sensor data, Spiro MPC can calculate and execute the optimal set of control moves needed to move a process to its most profitable limits.

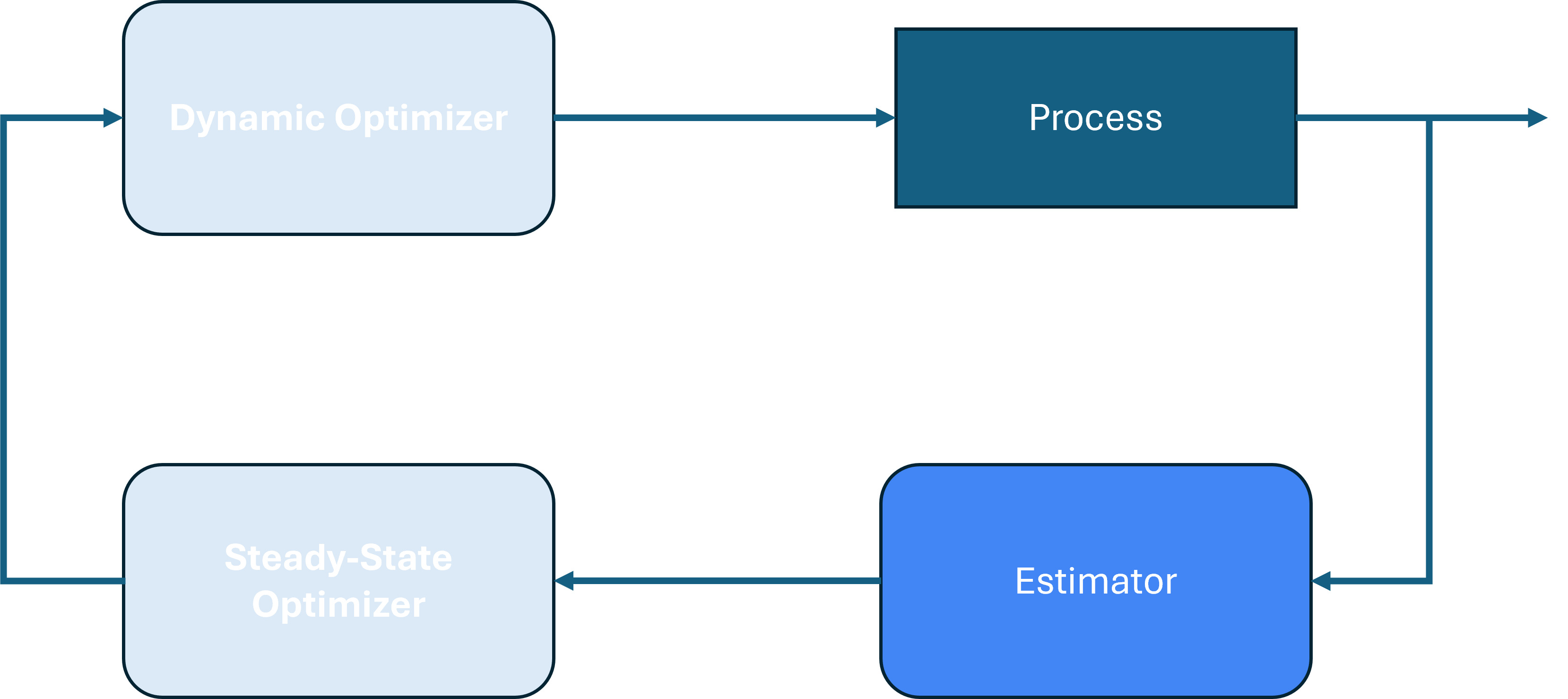

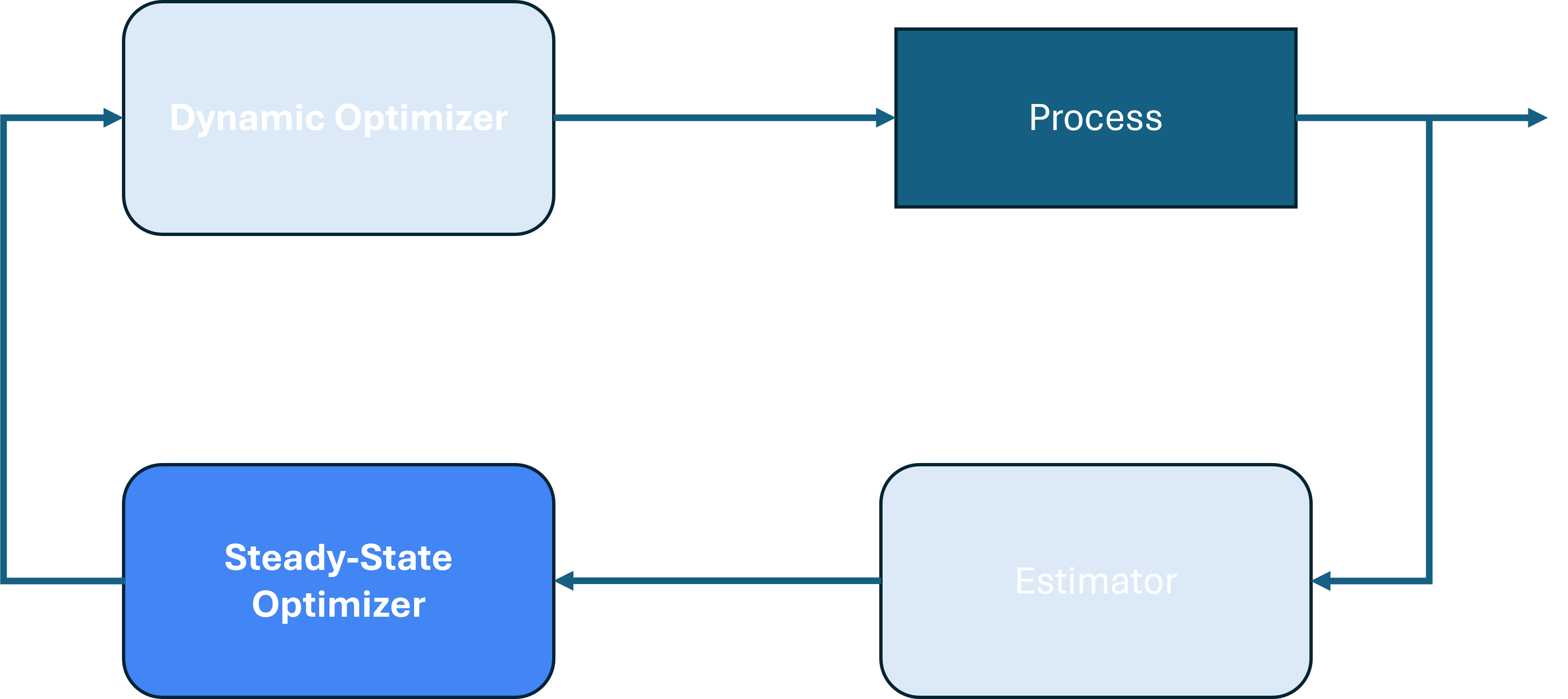

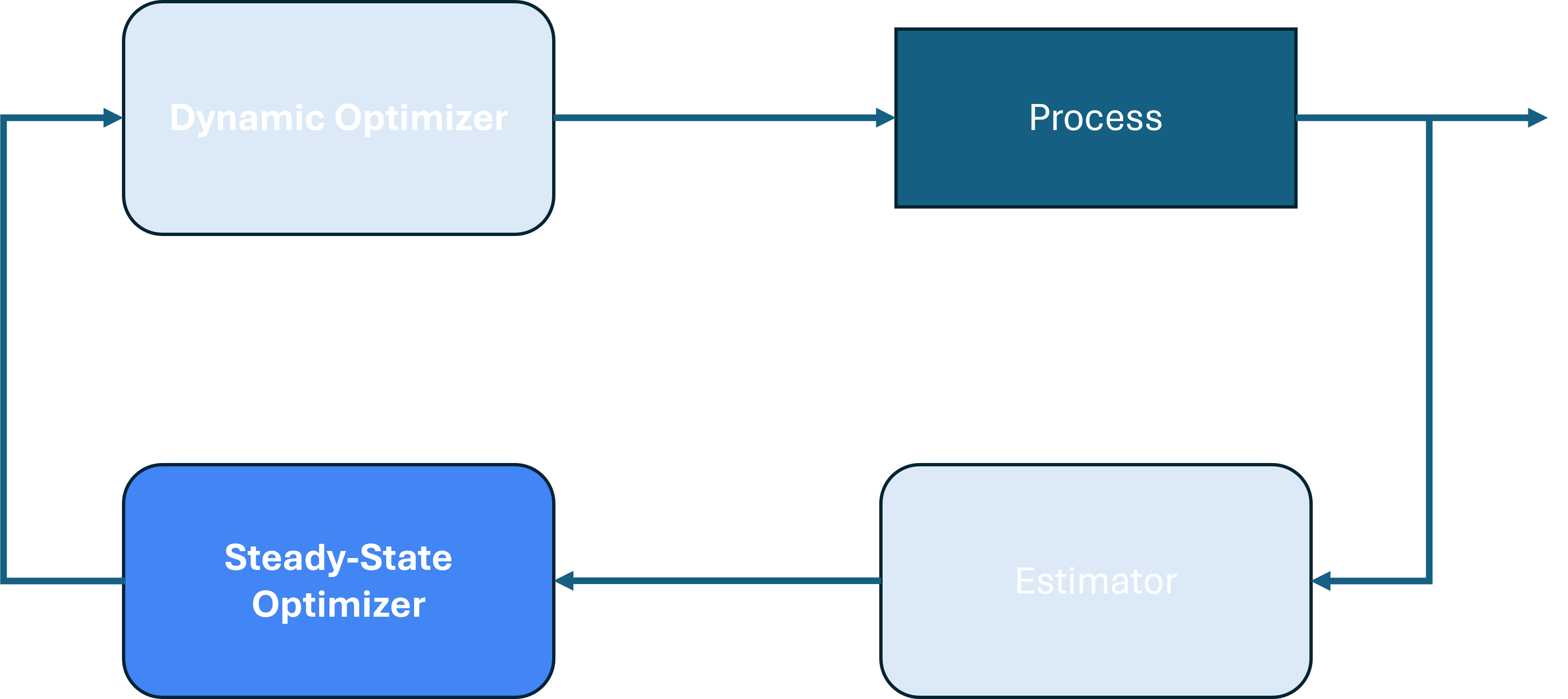

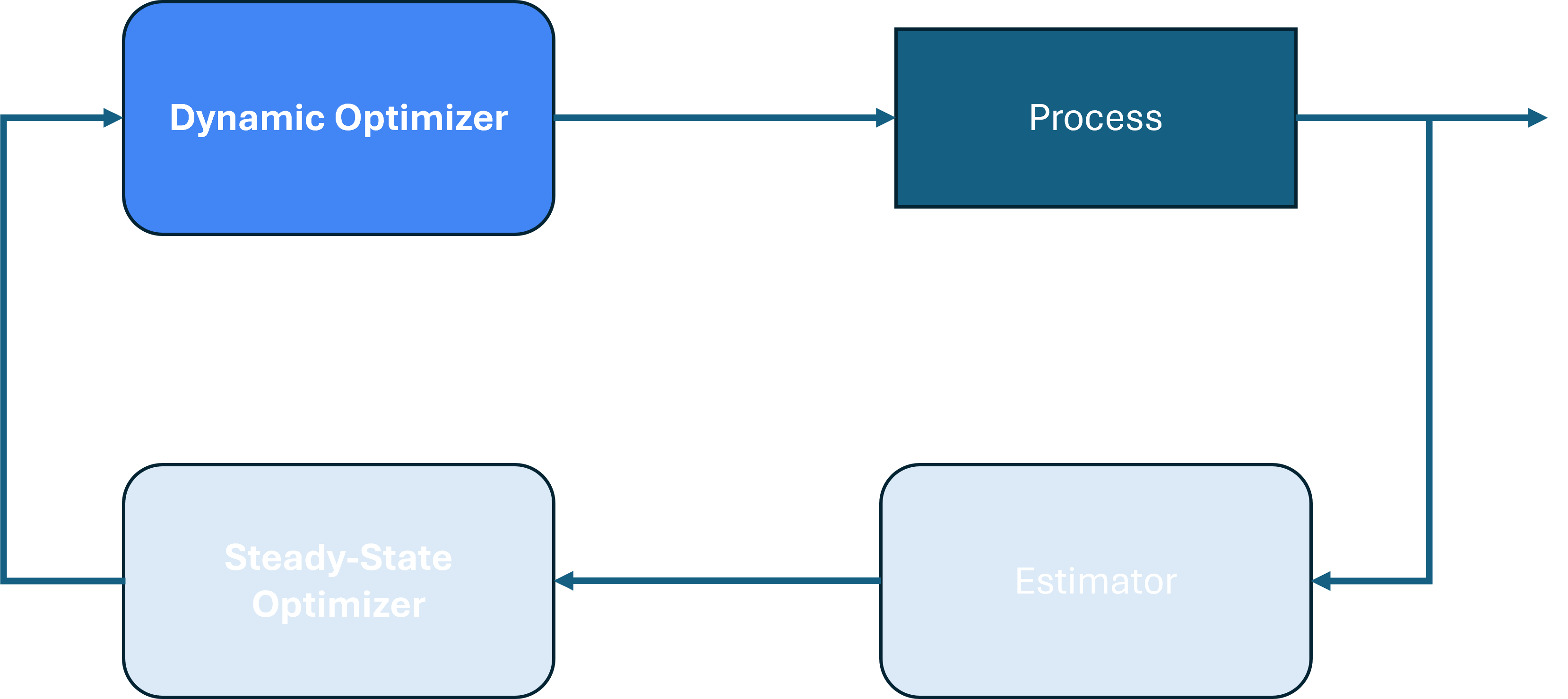

Spiro MPC embeds three powerful agents that work together to identify the most profitable operating point for the process and then plan how to move smoothly and safely to that operation, making sure all process and operating constraints are constantly satisfied.

Estimator

The estimator determines the current state of the process, such as temperature, pressure, or other variables, by using sensor data. It answers the question, where is the process operating right now? Since sensors can sometimes provide noisy or incomplete information, the estimator uses mathematical models to filter and predict the actual state of the system more accurately. This ensures that the control system has a good understanding of what’s happening in real time, even if there are measurement errors or missing data.

Steady-State Optimizer

The steady-state optimizer focuses on finding the best operating point for the process. Its goal is to decide on the ideal values of inputs, like adjusting flow rates or temperatures, to maximize performance, minimize costs, or achieve other desired outcomes, such as maintaining safety or efficiency. The steady-state optimizer answers the question, where do I want the process to operate?

Steady-State Optimizer

The steady-state optimizer focuses on finding the best operating point for the process. Its goal is to decide on the ideal values of inputs, like adjusting flow rates or temperatures, to maximize performance, minimize costs, or achieve other desired outcomes, such as maintaining safety or efficiency. The steady-state optimizer answers the question, where do I want the process to operate?

Dynamic Optimizer

The dynamic optimizer deals with how the process responds to changes over time, like sudden shifts in demand or disruptions in the process. It calculates a sequence of future control actions by predicting how the process will behave, adjusting inputs dynamically to guide the process smoothly from the current operating state to the optimal state all while minimizing errors or costs along the way. The dynamic optimizer decides, what is the best way to move the process from where it is now to where I want it to be?

Why choose Spiro MPC?

Why choose Spiro MPC?

Reliable, safe and secure

Spiro MPC is based on the CODESYS runtime which is in use in tens of thousands of industrial applications across the world. Its reliability is well proven.

Versatile, light & intuitive

The Spiro edge device supports open industry standards including IEC 61131-3, OPC UA, Fieldbus, Industrial Ethernet and Modbus. Furthermore, Spiro MPC is supplied with a configuration environment that supports the PLC Open XML file format and is fully compliant to IEC 61131-3, supporting all five programming languages.

Low maintenance

Spiro MPC can create, record and learn from data to continuously assess and improve the model of the process, meaning that Spiro MPC adapts to changes in the plant and delivers sustained benefits without a need for significant maintenance.

Maximum results

We developed Spiro MPC because manufacturers need better tools for turning data into actions, and better procedures to be able to safely push past operating within their comfort zone to instead operate at the limits of a process.

Arkema deployed Spiro’s technology as part of our commitment to the Paris Climate Agreement. We achieved sufficient steam savings to decommission a site boiler. The project delivered significant benefits through reduced energy costs and CO2 emissions.

Process Control Specialist, Arkema

Or schedule a live demo

Use the calendar below to schedule a meeting with a member of our team.

Or schedule a live demo

Use the calendar below to schedule a meeting with a member of our team.

Solutions

Products & Services

Industries

News & Updates

Company

Contact