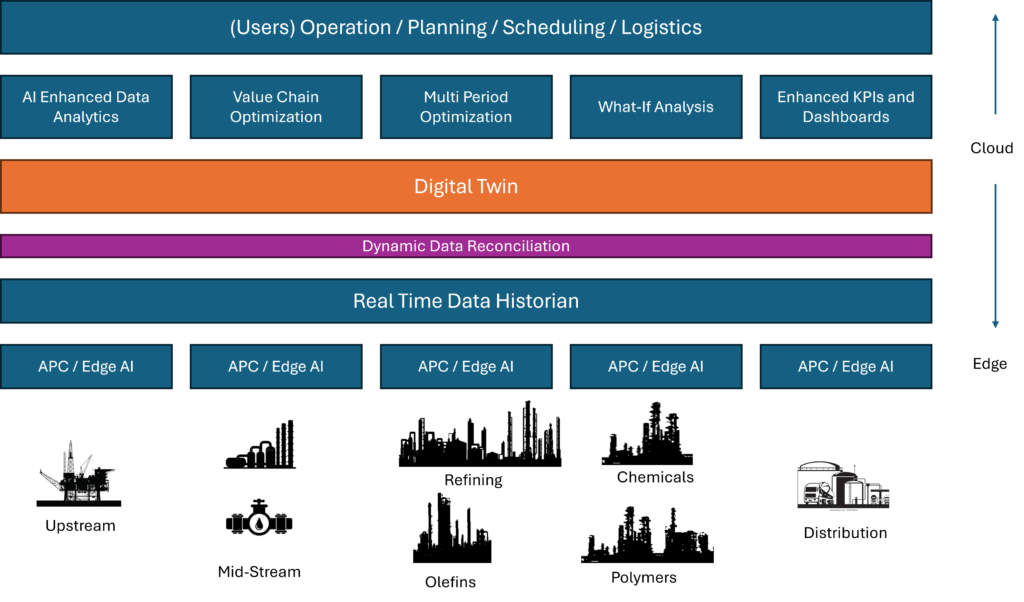

A digital twin is a real-time virtual model of a physical system that continuously collects data to simulate and optimize operations. This white paper explores how digital twins can be effectively applied to the energy value chain, addressing key challenges such as fluctuating market demands, operational inefficiencies, and environmental sustainability.

A digital twin of an integrated hydrocarbon energy supply chain, covering upstream, midstream, and downstream operations, facilitates real-time monitoring of operational conditions across the entire asset. By leveraging precise process models and thermophysical properties, it can track individual molecular components, such as hydrogen, methane, and CO2, from the wellhead to the end user or emission point.

By leveraging advanced simulation, AI, and machine learning, digital twins can improve performance, monitor environmental impact in real time, reduce costs, and strengthen supply chain resilience, ultimately increasing operating margins and optimizing return on capital employed.

Digital Twin for Energy Value Chain Optimization – Spiro – Sept 2024Download