Spiro Analytics

Accelerating Data-Driven Decision Making and Sustainability Goals.

Spiro Analytics

Accelerating Data-Driven Decision Making and Sustainability Goals.

Spiro Analytics provides an advanced, real-time data analytics platform designed to help organizations in energy, utilities, and industrial sectors achieve better operational efficiency, profitability, and sustainability. By utilizing high-precision data collection, real-time analytics, and powerful dashboard tools, Spiro Analytics enables companies to make informed decisions faster and streamline processes like emissions monitoring and performance optimization.

Real-Time Data-Driven Decision Making

Spiro Analytics enables companies to act on operational insights in real-time by collecting and processing data with nanosecond precision:

- Operational time-series data allows for rapid decision-making, improving the efficiency and profitability of industrial operations.

- Real-time data historian based on InfluxDB ensures high-volume data ingestion and low latency data queries providing fast and accurate information.

Sustainability and Emissions Monitoring

Spiro Analytics simplifies the challenge of tracking and mitigating emissions:

- Traditional tools like spreadsheets are cumbersome, leading to slow and inconsistent progress in meeting sustainability goals. Spiro Analytics automates emissions tracking, allowing for more precise and timely interventions.

- By helping organizations monitor emissions and optimize both legacy and new processes, Spiro Analytics accelerates the path to sustainability while enhancing operational performance.

Integration and Flexibility

Spiro Analytics supports seamless integration across various platforms and devices:

- Telegraf is a plugin-based tool that facilitates data collection from various sources, such as edge devices and data historians like OSI PI. It also supports pushing data back to OSI PI for comprehensive monitoring and integration.

- The platform’s open database model allows developers to access data through client libraries for various programming languages, such as C#, Python, Java, and more.

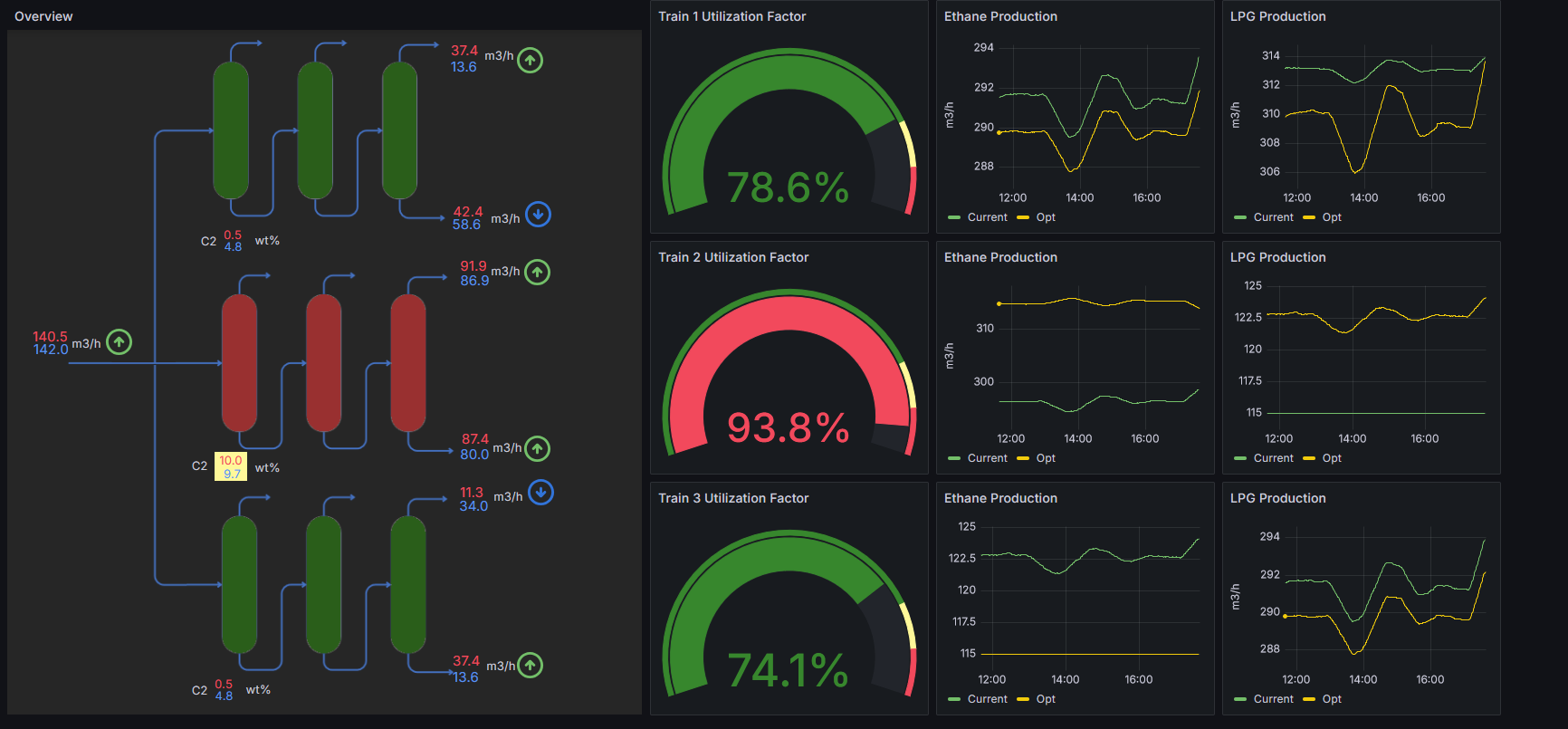

Real-Time Process Monitoring

Spiro Analytics is designed to provide real-time monitoring of systems, processes, and equipment, helping organizations uncover valuable insights and detect anomalies:

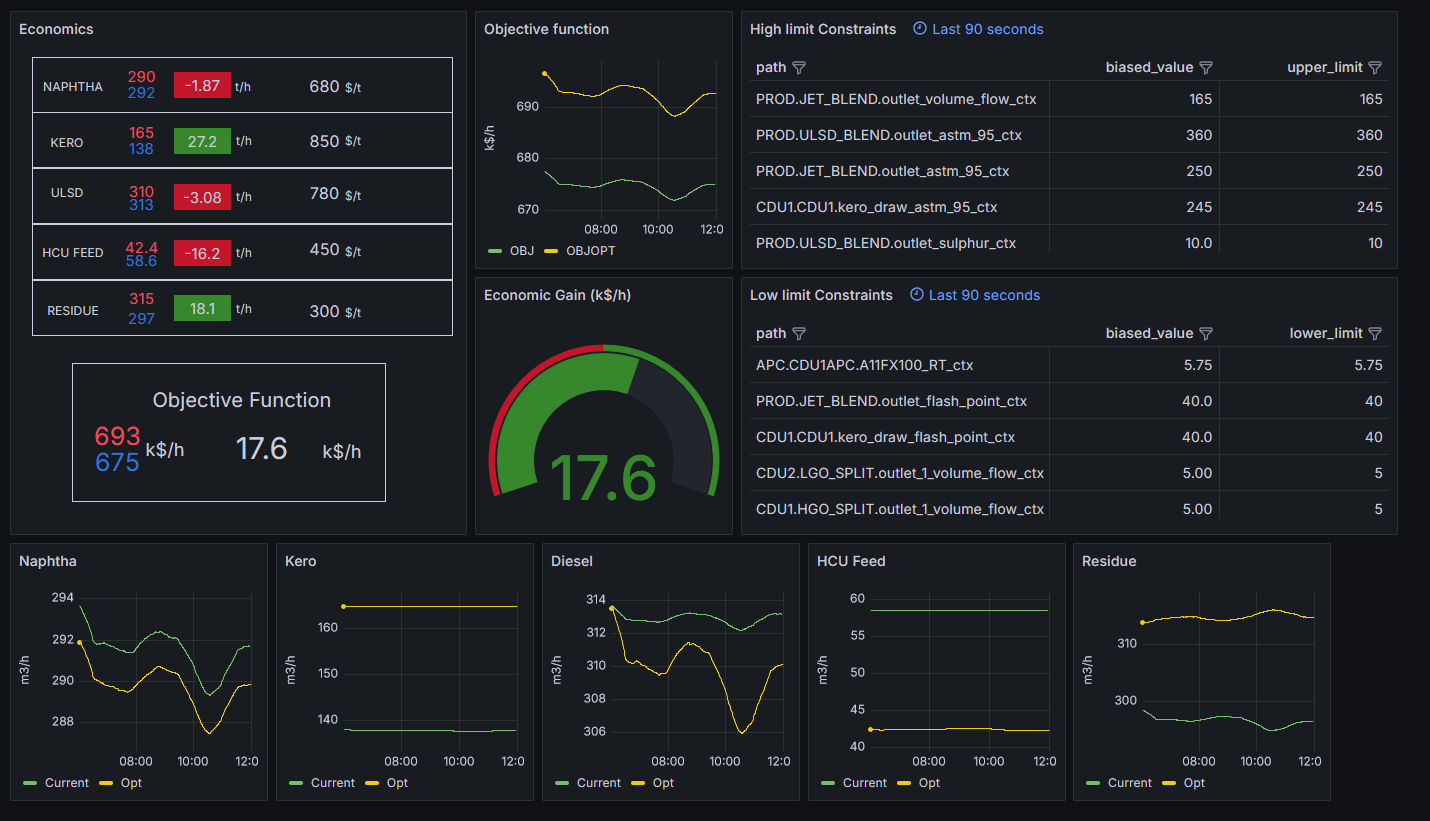

- Through integration with Spiro Digital Twin models, Dashboards offer visual insights into process parameters such as temperature, pressure, and flow, enabling users to track changes and make informed decisions.

- For example, in manufacturing facilities, real-time monitoring of boilers and utility systems can lead to optimized performance, energy savings, and proactive maintenance.

Performance Optimization and KPI Tracking

By using Spiro Analytics, businesses can set up real-time performance metrics and KPIs to optimize efficiency:

- The platform’s real-time calculation engine allows businesses to calculate efficiency metrics and store them for easy access and visualization on dashboards.

- For example, industries with high energy consumption can use Spiro Analytics to track energy efficiency in real-time, improving performance while reducing costs.

- Users can create custom dashboards in minutes, saving time on manual reporting and providing real-time insights into key performance indicators.

Custom Dashboards and Visualizations

Spiro Analytics offers highly customizable dashboards that allow users to visualize data from their processes, systems, and equipment:

- Users can create custom dashboards in minutes, saving time on manual reporting and providing real-time insights into key performance indicators.

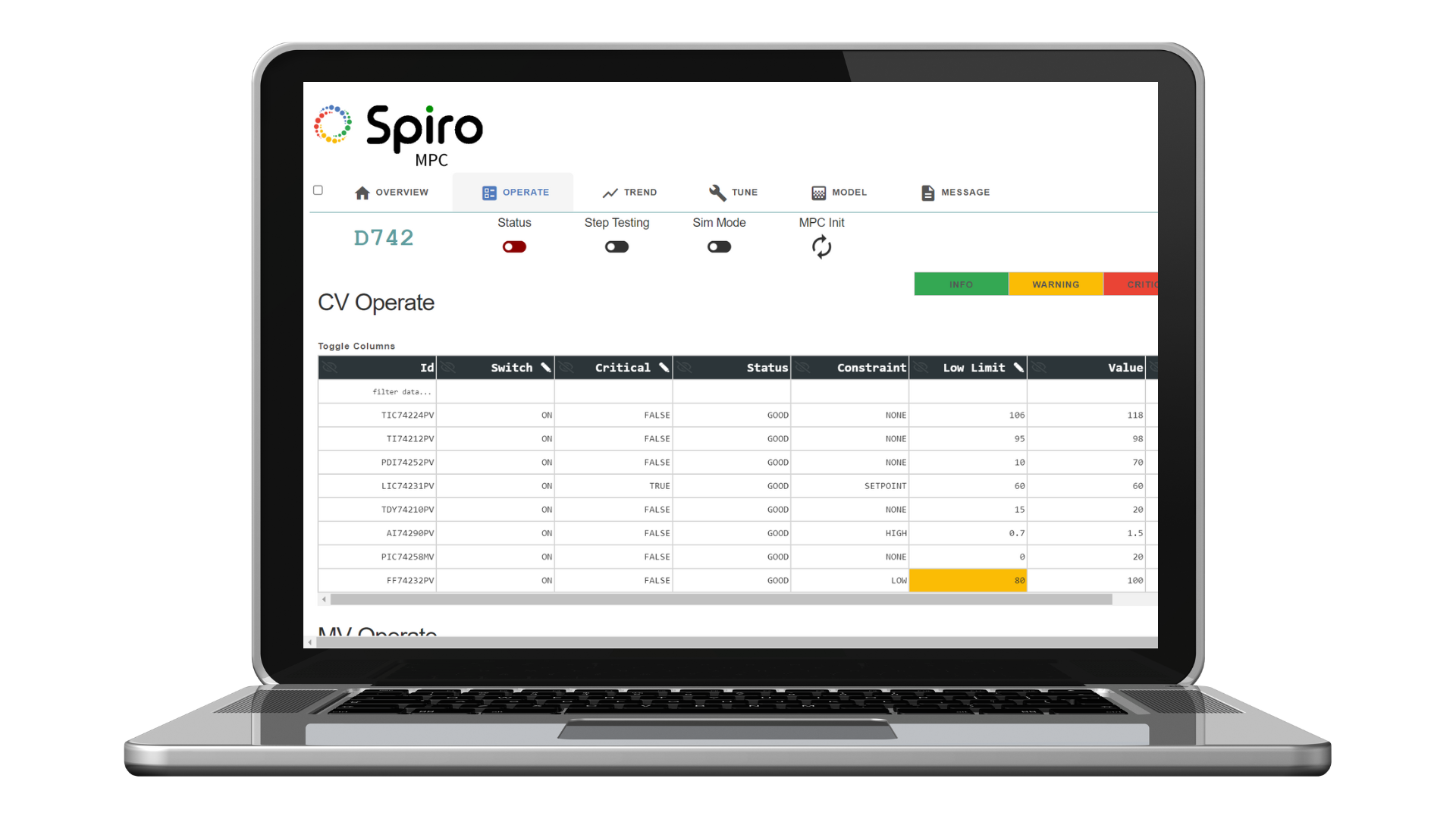

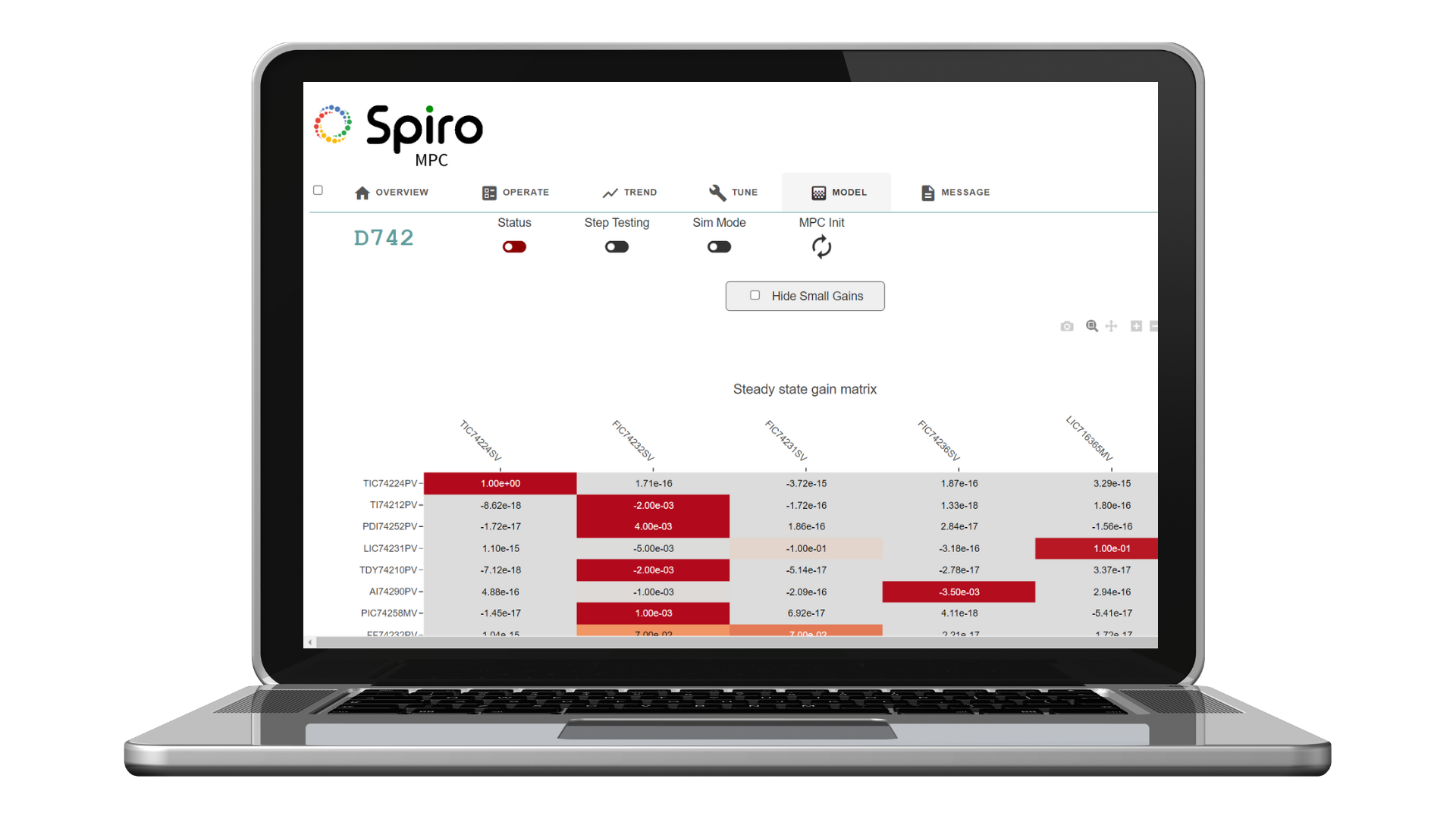

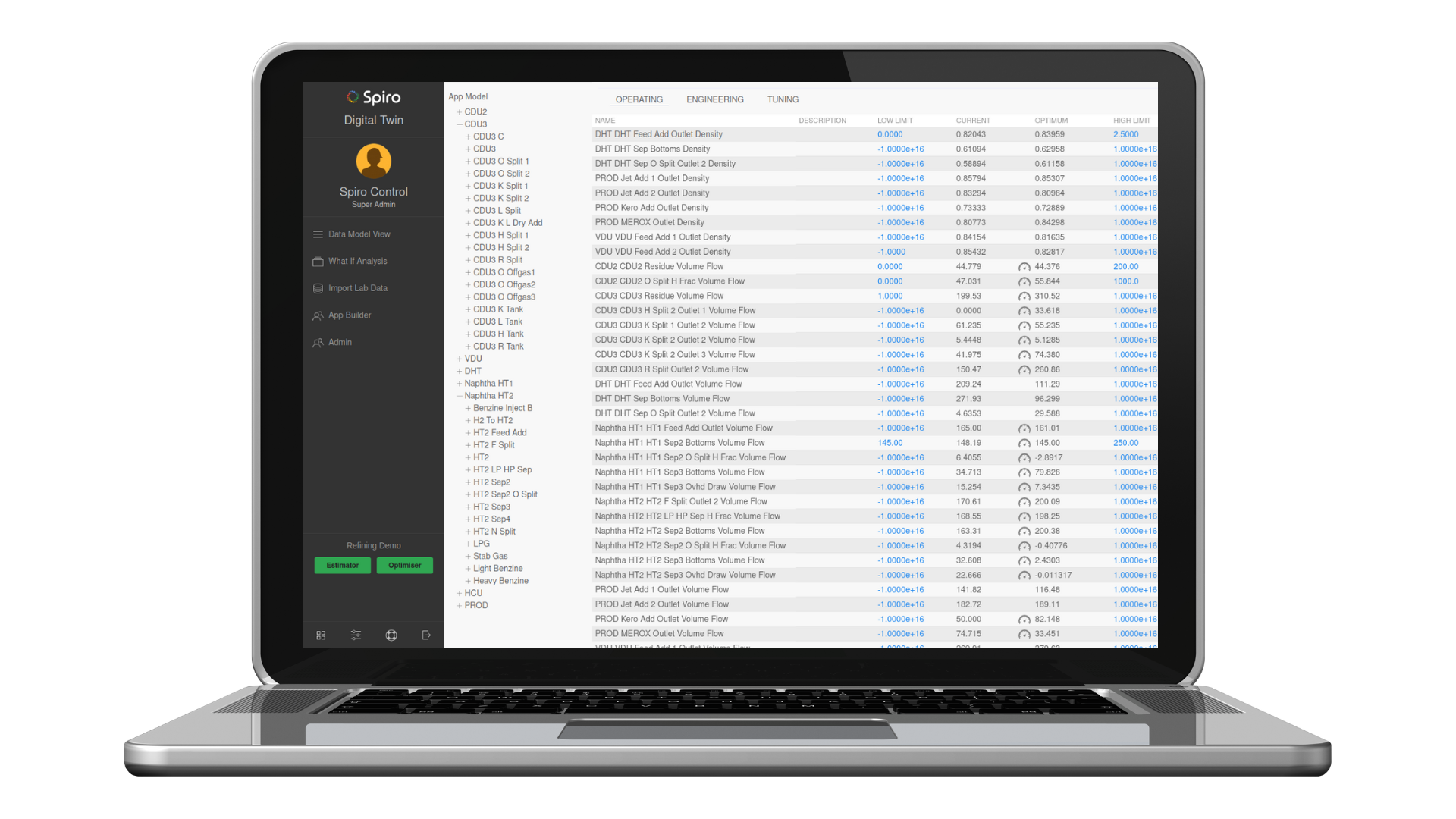

- Dashboards can display data from Spiro MPC, Spiro Digital Twin applications, and more, providing comprehensive visibility into operational performance and system health.

Spiro MPC and Digital Twin Integration

Spiro Analytics offers seamless data collection from Spiro applications, ensuring that key process information is consistently logged and accessible for real-time monitoring and historical analysis.

- Comprehensive Data Logging: All data from Spiro applications, including variables, tuning parameters, and diagnostic messages, are pushed to the data historian at the same frequency as the application. This ensures accurate, up-to-date information for analysis and troubleshooting.

- Historical Reproduction: The powerful data collection feature allows users to recreate the application status at any point in history, providing a detailed view of past performance for retrospective analysis and decision-making.

- Digital Twin Metrics: Data such as process stream compositions, temperature, pressure, flow, and unit operation parameters are available for trending and display on dashboards, offering real-time visibility into critical operational metrics.

Spiro Analytics – Integrated Performance Tools

Spiro offers preconfigured performance tools that take advantage of the features of Spiro Analytics to deliver performance insights into your regulatory and advanced control applications.

Spiro Performance Monitor

Spiro Analytics offers seamless data collection from Spiro MPC and Digital Twin applications, ensuring that key process information is consistently logged and accessible for real-time monitoring and historical analysis.

- Comprehensive Data Logging: All data from Spiro applications, including variables, tuning parameters, and diagnostic messages, are pushed to the data historian at the same frequency as the application. This ensures accurate, up-to-date information for analysis and troubleshooting.

- Historical Reproduction: The powerful data collection feature allows users to recreate the application status at any point in history, providing a detailed view of past performance for retrospective analysis and decision-making.

- Digital Twin Metrics: Data such as process stream compositions, temperature, pressure, flow, and unit operation parameters are available for trending and display on dashboards, offering real-time visibility into critical operational metrics.

Spiro PID Analytics

Spiro PID is a Spiro Analytics tool designed to continuously monitor and improve the performance of PID control loops in industrial processes. It provides real-time diagnostics and visualization of PID loop performance, valve and actuator behaviour, and sensor accuracy. This allows organizations to quickly identify and address poorly performing loops, optimize tuning parameters, and enhance process efficiency.

The tool offers multiple performance metrics and visual aids, including loop analysis summaries, impulse responses, and closed-loop Bode plots, making it easy to diagnose issues like non-linearity, valve stiction, or control overshoot. Spiro PID also supports integration with various data collection protocols such as OPC-UA, Modbus, and MQTT, making it compatible with a wide range of control systems.

Spiro PID helps industrial plants optimize PID controllers, leading to improved throughput, energy savings, and reduced process variability.

Reasons for installing Spiro PID Analytics

Identifying improperly tuned PID control loops and instrumentation issues is critical to optimising plant performance.

Identifying improperly tuned PID control loops and instrumentation issues is critical to optimising plant performance.

70%

of PID controllers are operating in automatic mode, 80% of which are operating suboptimally.

65%

of controllers are poorly tuned or de-tuned to mask control-related problems.

20%

of control systems are not properly configured to meet the control system objectives.

Contact Us

Let us know how we can help!

Email:

info@spirocontrol.com

Or schedule a live demo

Use the calendar below to schedule a meeting with a member of our team.

Or schedule a live demo

Use the calendar below to schedule a meeting with a member of our team.

Thornton Science Park, Cheshire, CH2 4NU, UK

info@spirocontrol.com

Solutions

Products & Services

Industries

News & Updates

Company

Contact