Olefins

AI and First Principles for Smarter Olefin Operations.

Olefins

Continuous measurement and visualisation of PID loop performance.

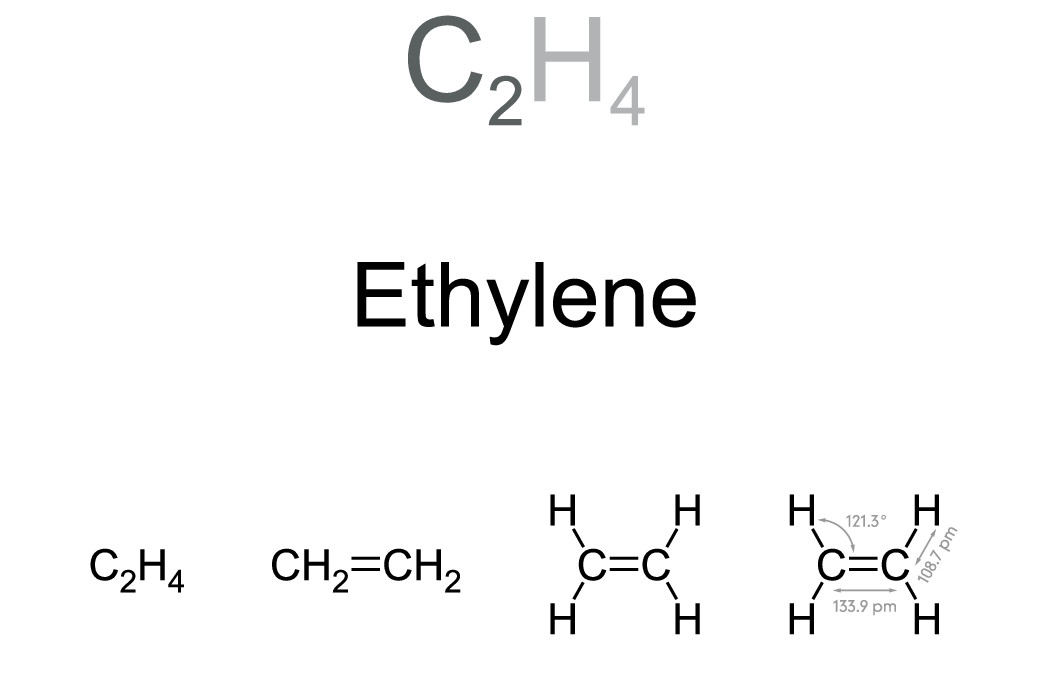

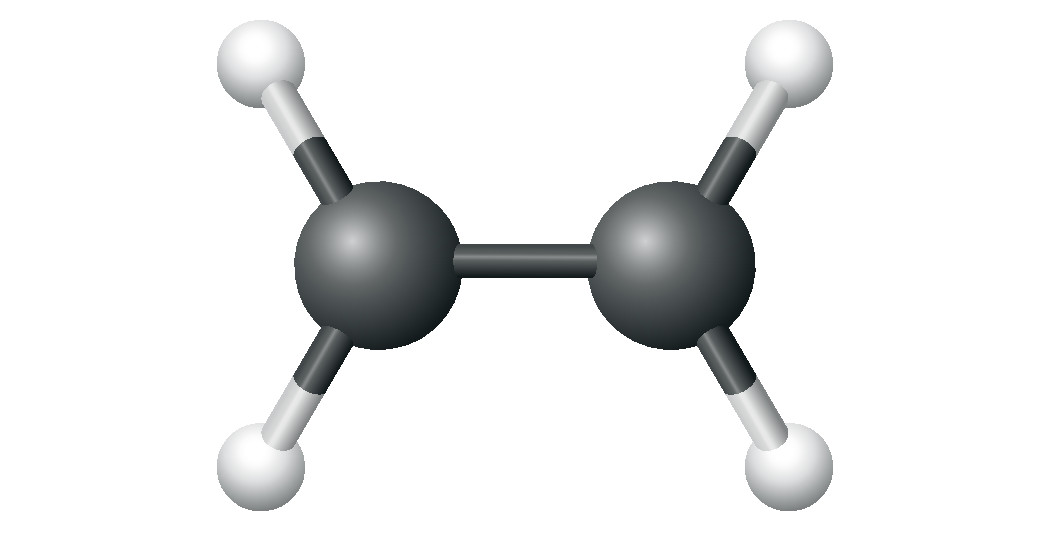

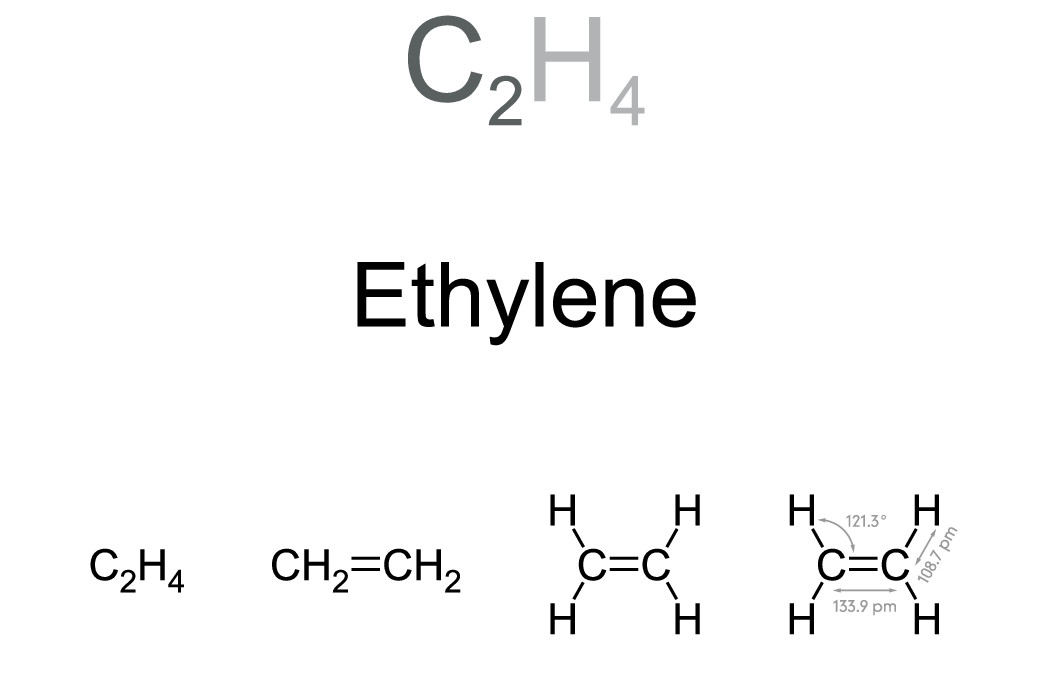

Light olefins are essential building blocks in the global chemical industry with production across all regions. Ethylene and Propylene are the most widely used commodity chemicals, they are used in products like plastic packaging, durable goods, and automotive products. Polyethylene and Polypropylene account for around 65% of global olefins demand.

Spiro Digital Twin utilizes AI-driven machine learning, thermodynamic models, and real-time data integration to optimize this important production process. It helps process operators to manage emissions, improve operational efficiency, address production constraints and bottlenecks, and to make informed planning decisions.

Spiro boasts one of the most experienced teams worldwide in olefins APC and RTO projects, with our consultants collectively completing over 35 global projects. Through our work in olefins and related gas plants, Spiro has delivered more than $100 million in audited benefits. We provide comprehensive turnkey project and consulting services. If you’re interested in discussing olefins, a subject we’re passionate about, feel free to contact us.

Enhanced Operational Efficiency

Spiro Digital Twin allows operators and engineers to monitor and optimize production processes in real-time, using advanced data reconciliation algorithms and dynamic models that capture transient process operations:

- Real-time decision-making with data-driven insights.

- Improved furnace operations through AI-enhanced models that optimize furnace severity, coking rates, and decoking schedules.

- Maximized profitability by predicting constraints and debottlenecking scenarios, which optimize throughput and resource allocation.

Sustainability and Emission Management

By monitoring and forecasting environmental emmissions and providing Key Performance Indicators for carbon emissions, Spiro Digital Twin enables olefins plant operators to monitor their environmental compliance and performance:

- Carbon emission index (CEI) is one of the primary sustainability measures for CHG emissions used by Solomon in their worldwide olefin performance index as a measure of scope 1 and 2 emissions.

- Spiro’s AI enhanced digital twin models predict the impact of fuel composition, combustion, and flaring on emissions, enabling real-time adjustments to meet environmental standards.

Process Optimization

- What-if scenario analysis allows Olefins operators, planners and engineers to simulate multiple operational scenarios and optimize resource allocation and costs.

- Closed-loop optimization provides improved plant performance by adjusting key operational operating parameters in real time to maximize production, minimize resource use and ensure full downstream equipment utilization.

Use Case – Emission Monitoring and Forecasting

- Spiro Digital Twin assists organizations in monitoring and forecasting emissions based on operational variables such as fuel composition and production rates. This data helps achieve:

- Proactive emission management by predicting and mitigating the impact of operational changes on sustainability goals.

- Regulatory compliance by using real-time emission data to meet local and international standards.

Use Case – Furnace Optimization

Furnaces are a critical part of the olefins production process. Spiro’s deep learning furnace models improve furnace efficiency by:

- Predicting effluent composition and helping operators optimize furnace severity and fuel usage.

- Reducing downtime by forecasting coking rates and optimizing decoking schedules to extend furnace run lengths.

- Improving APC (Advanced Process Control) applications by providing accurate inferential variables.

Use Case – Simulation and Optimization

Spiro Digital Twin enables operators to simulate “what-if” scenarios and make informed decisions regarding:

- Fractionation and reaction unit operations, enhancing the accuracy of stream composition predictions.

- Constraint management through non-linear optimization models that balance downstream processes and predict operational bottlenecks.

Spiro Digital Twin offers a comprehensive solution for olefin production optimization. By combining AI, machine learning, and first-principal models, the platform enhances decision-making, increases efficiency, and supports sustainability initiatives. Whether used for emission monitoring, furnace optimization, or constraint management, Spiro Digital Twin is a vital tool for ensuring competitiveness and operational excellence in the petrochemical industry.

Contact Us

Let us know how we can help!

Email:

info@spirocontrol.com

Or schedule a live demo

Use the calendar below to schedule a meeting with a member of our team.

Or schedule a live demo

Use the calendar below to schedule a meeting with a member of our team.

Thornton Science Park, Cheshire, CH2 4NU, UK

info@spirocontrol.com

Solutions

Products & Services

Industries

News & Updates

Company

Contact