Upstream

Optimizing Upstream Oil and Gas Operations with Spiro MPC and Spiro Digital Twin.

Upstream

Optimizing Upstream Oil and Gas Operations with Spiro MPC and Spiro Digital Twin.

The upstream oil and gas industry, encompassing exploration, drilling, and production, is the first link in the energy value chain. Upstream companies perform well when oil and gas prices are high and production volumes are robust, benefiting particularly from unconventional reserves like shale oil and gas. Key trends shaping the industry include rising capital expenditures, energy transition efforts, and market volatility.

The Permian Basin, located in West Texas and southeastern New Mexico, has become a key hub for unconventional oil and gas production, driving significant U.S. output growth. With its vast reserves and advanced drilling techniques like hydraulic fracturing, the region plays a pivotal role in ensuring U.S. energy independence.

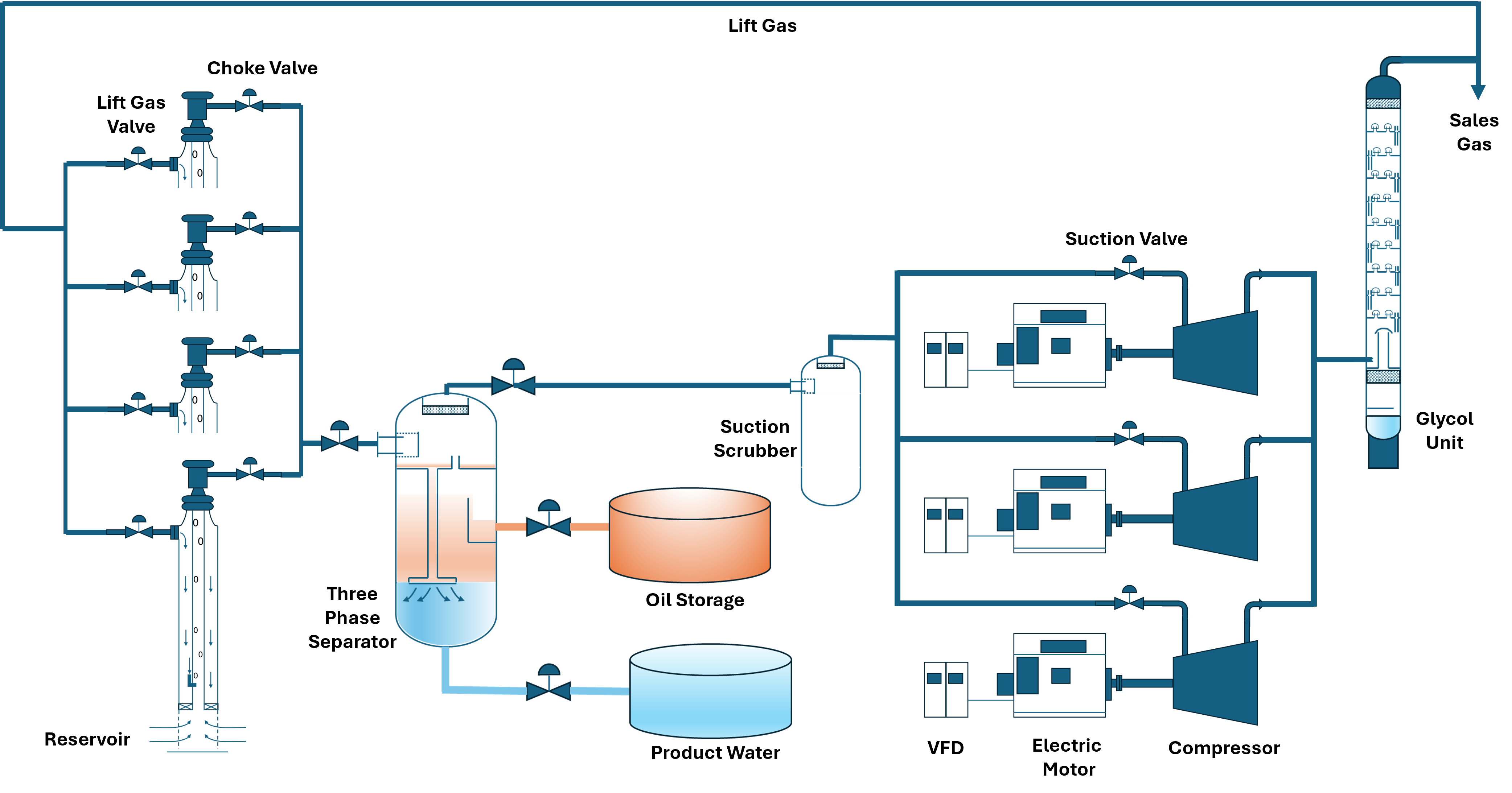

Spiro’s MPC and Digital Twin solutions provide advanced optimization and stabilization capabilities for upstream oil and gas operations. These tools leverage real-time data, AI, and optimization algorithms to enhance well production, optimize gas lift allocation, and improve compressor performance. By adopting these technologies, operators can achieve greater efficiency, lower operating costs, and reduce environmental impact, all while minimizing manual intervention and optimizing well conditions under changing field dynamics.

Spiro MPC on the PLC Network

Although APC is a well-established technology in downstream oil and gas operations, its adoption upstream is less widespread. One reason for the slow adoption is the remote and distributed nature of the operations, another is the common use of PLC and SCADA control systems rather than DCS which are more common downstream.

Unlike competitor’s technology, Spiro can be deployed on either a DCS or a PLC network. PLCs are often deployed on remote assets like upstream production facilities, they are also commonly deployed on packaged or rental units like compressors. Deploying Spiro MPC directly on the PLC device or PLC network puts the technology in the hands of your on-site instrument technicians rather than APC specialists and consultants. Other advantages include: Low Latency and Fast Execution, Cost-Effective Implementation, Reliability and Robustness, Enhanced Cyber Security.

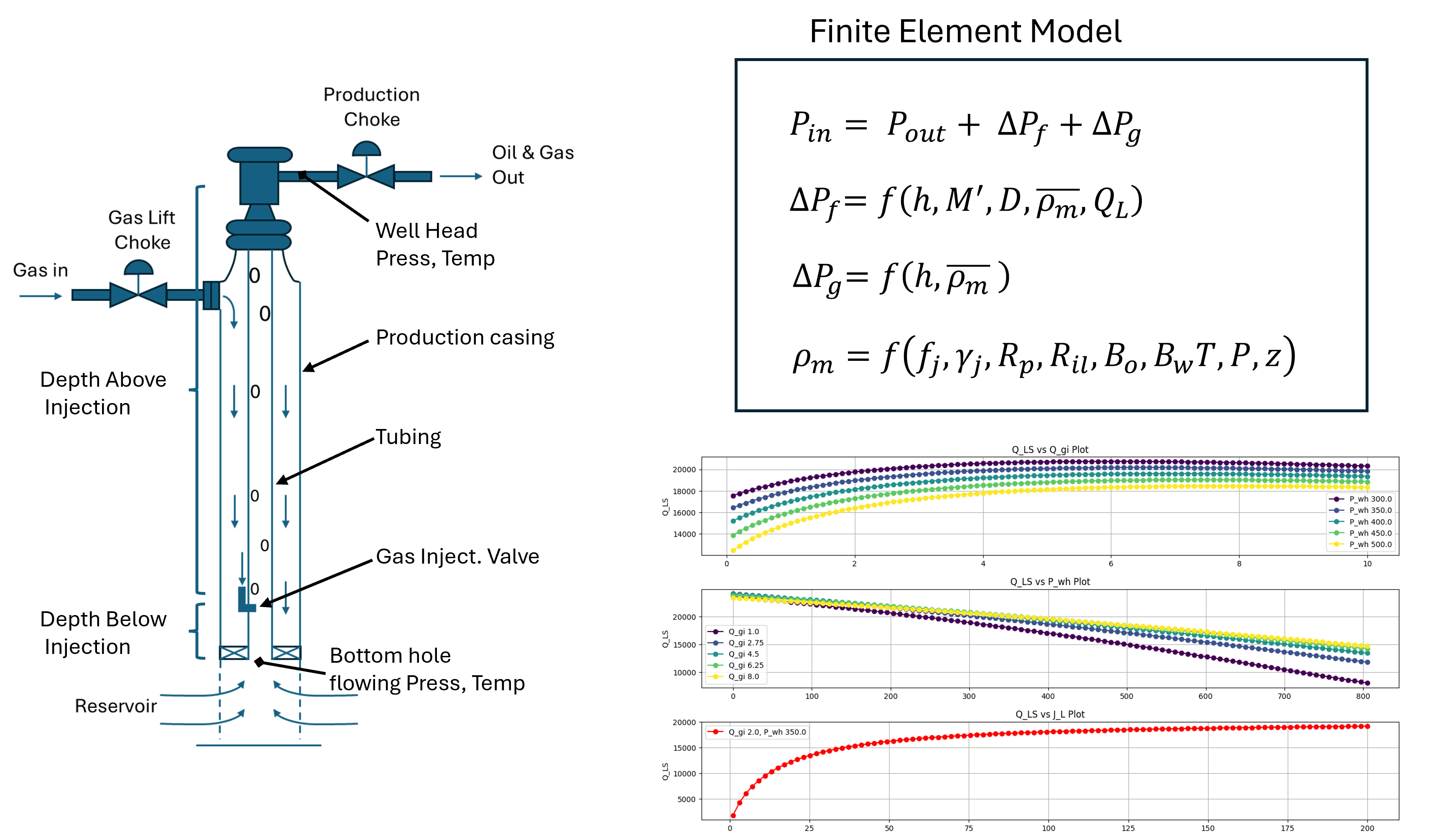

Automated Well Production

A centralized Digital Twin application can provide direction to PLC embedded Spiro MPC applications dispersed across a wide geographical area. While the Digital Twin allocates production on individual assets across the network, the MPC adjusts securely the choke valve and lift gas rates at the well head. This coordinated application can provide automated well production, reduce flaring and avoid well shut ins.

Compressor Station Optimization

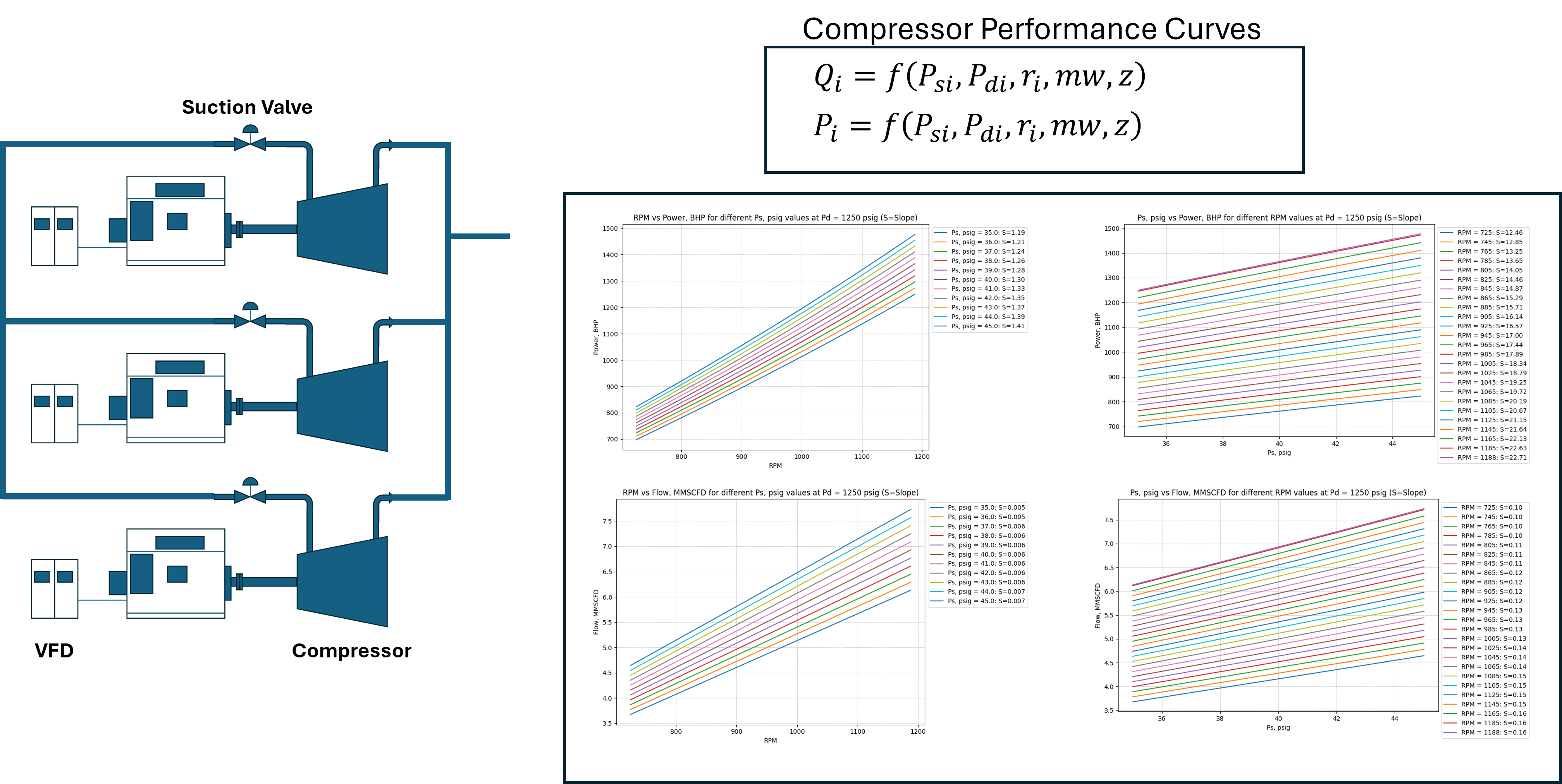

Spiro MPC offers real-time optimization for compressor stations, ensuring efficient load sharing and power consumption:

- By dynamically adjusting parameters like suction pressure, RPM, and compressor load, Spiro MPC ensures optimal compressor performance, which leads to energy savings and reduced operating costs.

- This optimization is key in reducing greenhouse gas emissions, aligning with broader sustainability goals.

Use Case – Gas Allocation Optimization for Artificial Lift

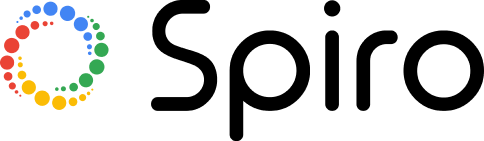

Continuous flow gas lift is a common artificial lift method used to enhance oil extraction, but with limited gas supply, operators face challenges in maximizing production:

- Spiro Digital Twin uses a nonlinear optimization algorithm to allocate gas injection rates across wells in a way that maximizes oil production.

- This solution adjusts injection rates based on the performance curve of each well, optimizing production and reducing excess gas use.

-

Spiro Digital Twin enables real-time optimization of gas allocation across wells, maximizing oil production under constrained gas injection conditions.

- This automated system minimizes gas injection inefficiencies and operational costs, reducing the need for manual oversight.

Use Case – Well Production Stabilization

In complex oil fields, well production is prone to instability due to fluctuating reservoir conditions and equipment limitations:

- Spiro MPC stabilizes well production by continuously adjusting critical variables like bottom hole pressure and flowline pressure based on real-time data, ensuring steady and reliable output.

- This real-time control minimizes disruptions and costly downtime associated with well trips, significantly improving overall field productivity.

Use Case – Compressor Station Load Optimization

At compressor stations, balancing the load across multiple compressors with varying characteristics is essential for optimal performance:

- Spiro MPC is deployed within programmable logic controllers (PLCs) to control compressor operations based on performance curves derived from compressor characteristics.

- This load-sharing optimization reduces energy consumption and ensures that compressors operate within their optimal ranges, contributing to both cost savings and operational efficiency.

Spiro MPC and Spiro Digital Twin deliver transformative solutions for upstream oil and gas operations by optimizing well production, stabilizing operations, and improving compressor performance. These tools leverage real-time data and advanced predictive control algorithms to maximize production, reduce operational costs, and enhance overall field efficiency. By adopting Spiro’s solutions, operators can overcome the challenges of dynamic field conditions, achieve more stable production, and reduce environmental impacts, all while minimizing manual intervention and optimizing operational decision-making.

Or schedule a live demo

Use the calendar below to schedule a meeting with a member of our team.

Or schedule a live demo

Use the calendar below to schedule a meeting with a member of our team.

Solutions

Products & Services

Industries

News & Updates

Company

Contact