Chemicals

Optimize Process Operations and Maximize Efficiency in the Chemicals Industry with Spiro Solutions.

Chemicals

Optimize Process Operations and Maximize Efficiency in the Chemicals Industry with Spiro Solutions.

Spiro’s solutions enable chemical manufacturers to enhance operational efficiency, optimize resource use, and ensure high product quality. Our tools provide real-time control and analytics, helping manufacturers address the growing pressures to improve production capacity while minimizing costs. By leveraging edge computing, AI and inferential models, Spiro delivers measurable benefits, including energy savings, increased stability, and significant financial returns.

‟Arkema deployed Spiro’s technology as part of our commitment to the Paris Climate Agreement. We achieved sufficient steam savings to decommission a site boiler. The project delivered significant benefits through reduced energy costs and CO2 emissions.”

— Process Control Specialist, Arkema

Enhanced Process Control and Stability

Spiro MPC (Multivariable Predictive Control) provides a powerful control system that automates real-time adjustments to key process variables. This leads to:

- Increased production stability by maintaining optimal process conditions, reducing deviations, and allowing human operators to manage complex environments more easily.

- Improved product quality through continuous fine-tuning of variables, which minimizes the variability of key outputs.

- Reduced operating costs by optimizing control combinations and limiting excess resource usage, especially in energy-intensive processes.

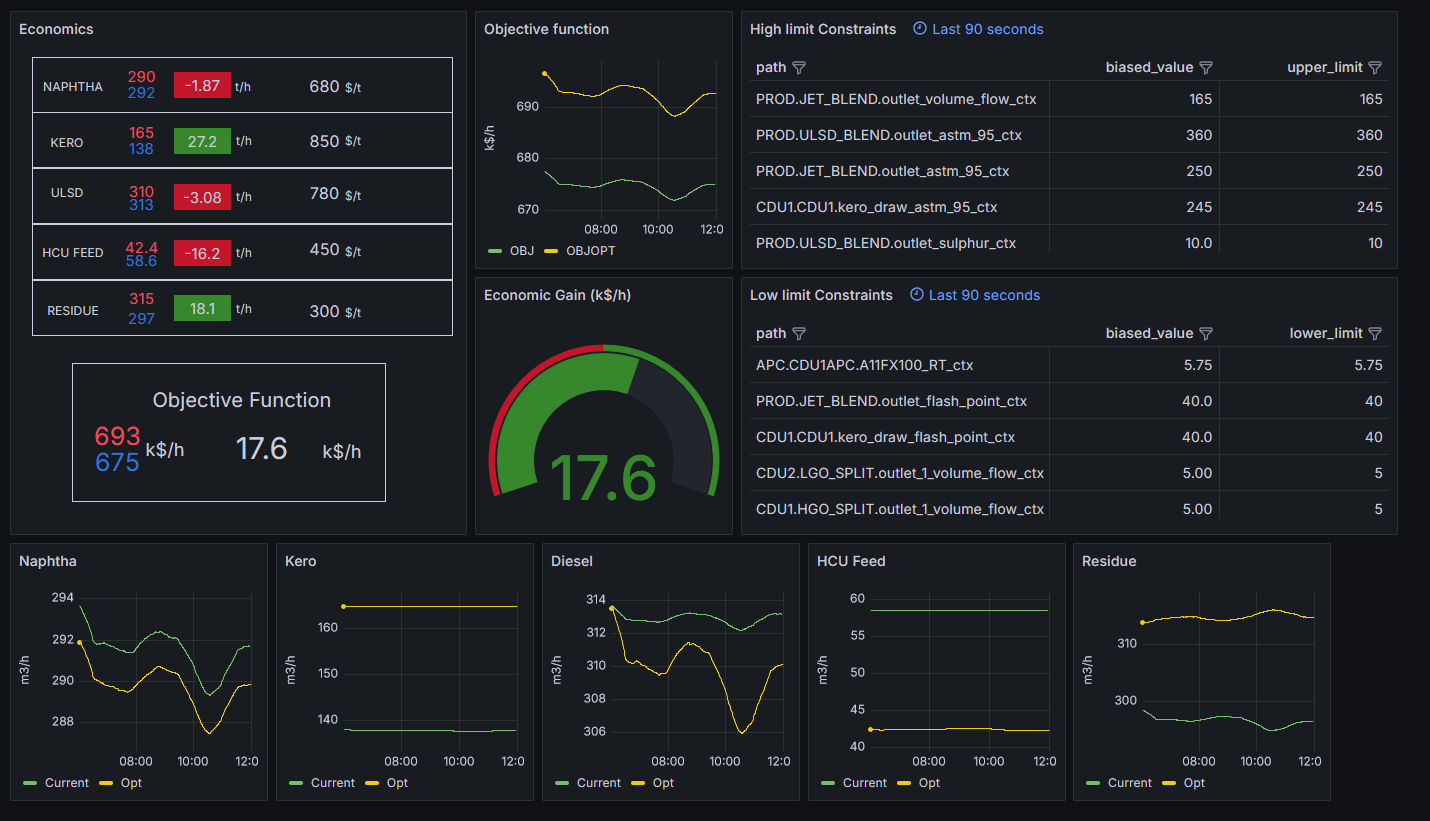

Plant-Wide Optimization

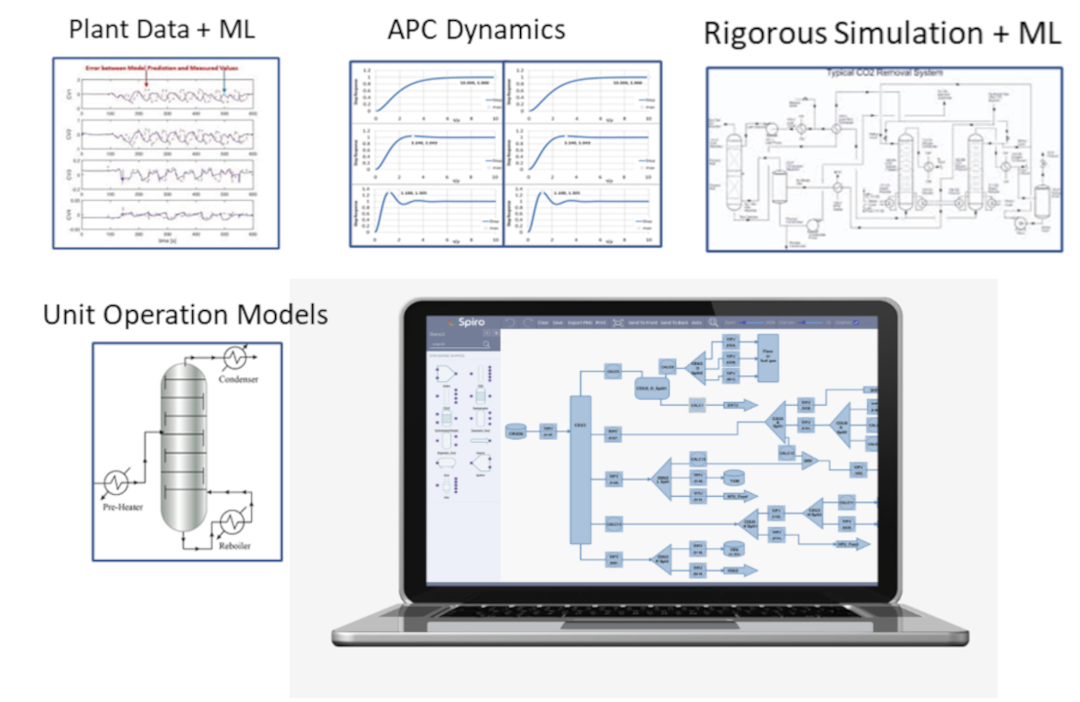

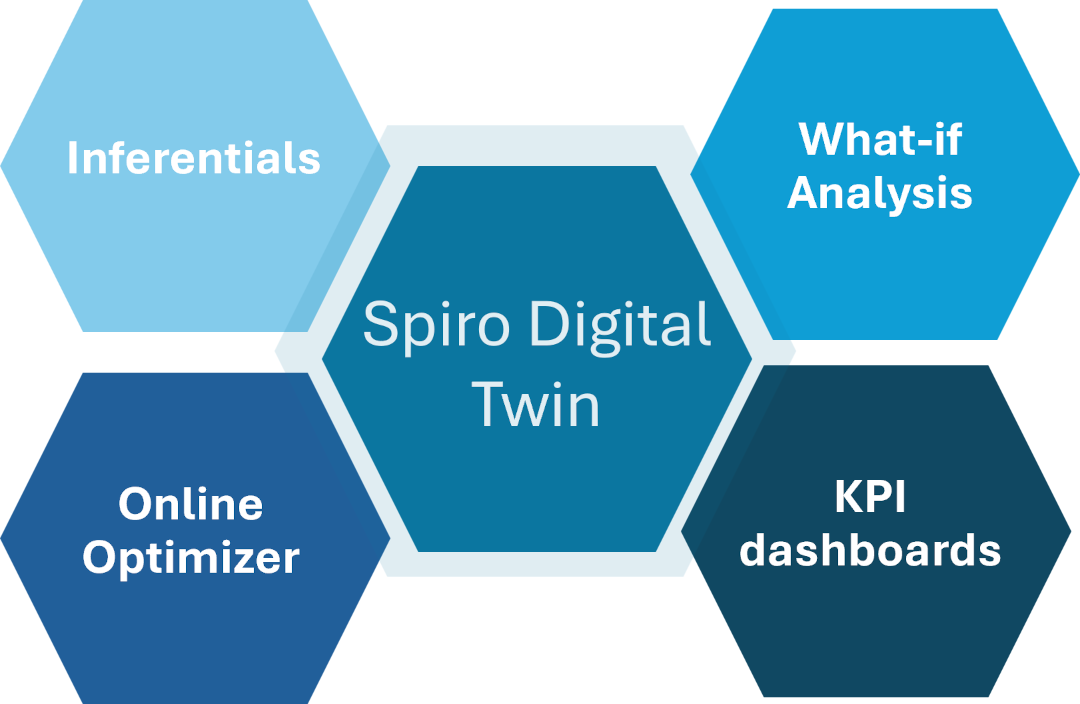

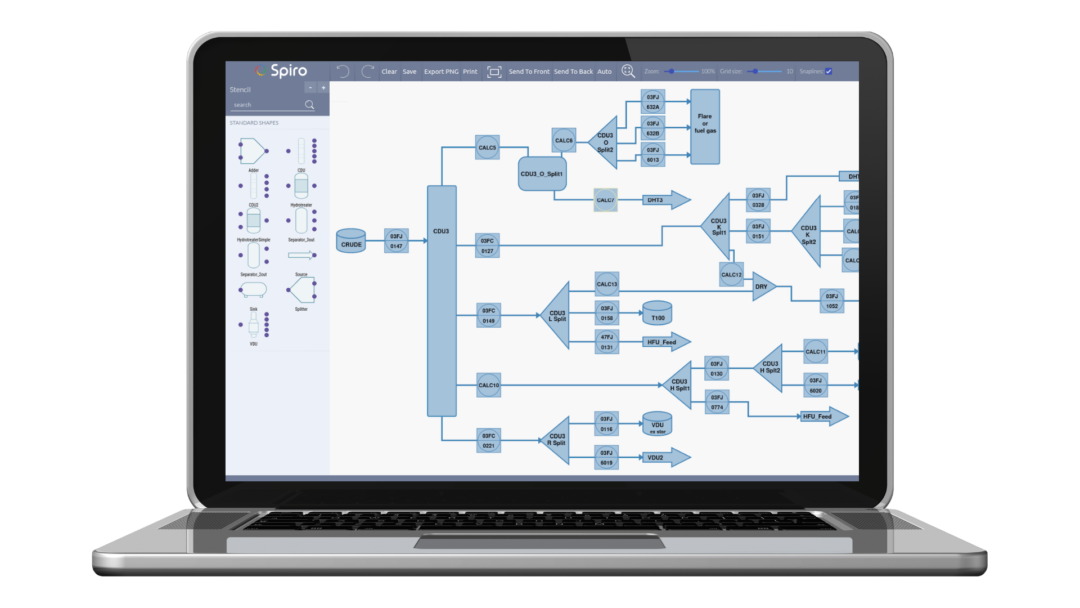

Spiro goes beyond unit-specific optimization to achieve holistic, plant-wide optimization, through Spiro Digital Twin and Spiro Cooperative Control to enhance overall plant performance:

- For example, chemical and petrochemical plant operators have typically seen a 2-5% increase in operating capacity, with financial benefits ranging from $1-12 million per year.

- By synchronizing individual controllers and subsystems through cooperative distributed control, Spiro’s software ensures that each unit operates with full awareness of the broader process objectives.

Real-Time Analytics and Data Utilization

Spiro Analytics offers real-time analysis of plant data, allowing for immediate insights and operational adjustments:

- Edge analytics processes data at the source, minimizing data lag and eliminating the need for cloud deployment. This real-time processing helps in rappid detection of faults and process deviations.

- The solution is designed to be user-friendly, allowing control and process engineers to perform analysis without requiring specialized data science expertise.

Use Case – Multivariable Predictive Control with Spiro MPC

In highly dynamic and interactive environments, such as those found in chemical manufacturing, traditional control systems often fall short in maintaining optimal conditions. Spiro MPC’s state space models provide robust control solutions that are easy to deploy and maintain. They enable manufacturers to manage complex processes with real-time precision:

- Increased stability leads to fewer process disruptions, translating into higher production output.

- Standard deviation reduction in control variables allows processes to remain within optimal operating ranges more consistently.

Plant-Wide Energy Optimization

In a plant with centralized steam utilities supporting various consumer units like reboilers, evaporators, and turbines, Spiro MPC can optimize the entire utility network:

- Studies show that plants can reduce specific energy consumption by ~10%, yielding annual savings of between £0.1-1.0 million depending on the size of the plant.

- This optimization is achieved through coordinated control across units, ensuring that energy resources are allocated and used efficiently. The controller also ensures efficient steam system operation by minimizing unrecoverable energy loss through let down valves and venting.

Real-Time Analytics and Inferentials

Spiro Analytics transforms how plants handle large volumes of production data by performing analytics directly at the edge:

- This enables immediate fault detection and diagnostics, allowing for rapid responses that prevent costly downtime or product quality issues.

- Traditional data analysis methods may store data in warehouses for extended periods before analysis. In contrast, Spiro Analytics ensures instant action by analyzing data in real time.

- Spiro PID is an analytics tool that delivers continuous measurement and visualization of PID control loop performance, valve/actuator anomalies, and sensor performance. By understanding the cause of poorly performing control loops, users can make significant improvements to process efficiency.

Spiro’s solutions, including Spiro MPC, Spiro Digital Twin and Spiro Data Analytics, offer transformative benefits to the chemicals industry, helping manufacturers optimize operations, improve energy efficiency, and maximize resource utilization. By leveraging cutting-edge technologies such as multivariable predictive control, real-time edge analytics, and distributed cooperative control, Spiro enables chemical manufacturers to stay competitive in a rapidly changing industry. With proven financial benefits and increased operational stability, Spiro is an essential tool for the modern chemical manufacturing facility.

Contact Us

Let us know how we can help!

Email:

info@spirocontrol.com

Or schedule a live demo

Use the calendar below to schedule a meeting with a member of our team.

Or schedule a live demo

Use the calendar below to schedule a meeting with a member of our team.

Thornton Science Park, Cheshire, CH2 4NU, UK

info@spirocontrol.com

Solutions

Products & Services

Industries

News & Updates

Company

Contact