Food and Beverages

Driving Operational Excellence in Food & Beverage Manufacturing with Spiro’s Solutions.

Food and Beverages

Driving Operational Excellence in Food & Beverage Manufacturing with Spiro’s Solutions.

The food and beverage industry faces pressure to improve efficiency and sustainability, with energy accounting for 15% of manufacturers’ costs and margins around 5-6%. Rising costs, a shortage of skilled labour, and growing competition mean manufacturers must focus on energy efficiency and automation to relieve pressure on margins. Technologies like AI and IIoT (Industrial Internet of Things), are increasingly important. These tools can help manufacturers optimize energy use, cut emissions, and lower costs, providing a critical competitive edge.

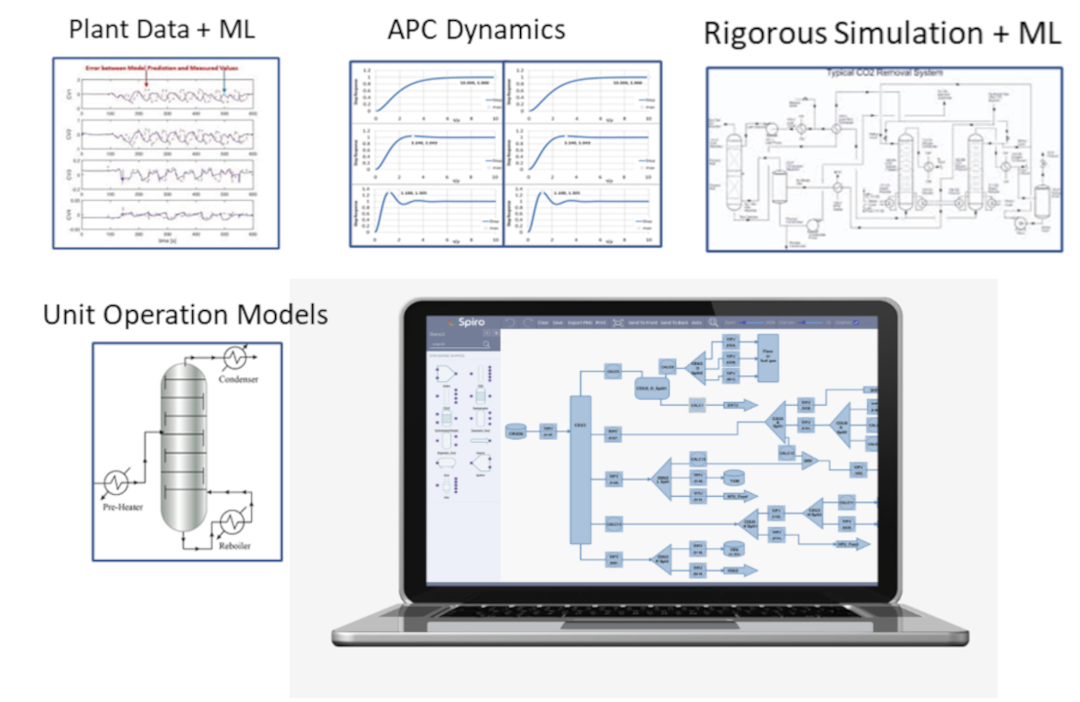

Spiro’s solutions equip food and beverage manufacturers with the tools necessary to achieve operational visibility, process optimization, and cost reduction. By automating control systems and enabling real-time data analytics, Spiro ensures consistent production quality, increases process stability, and enhances plant-wide optimization. These tools empower manufacturers to navigate challenges related to disturbances, variability in production, and energy efficiency, ultimately driving operational excellence.

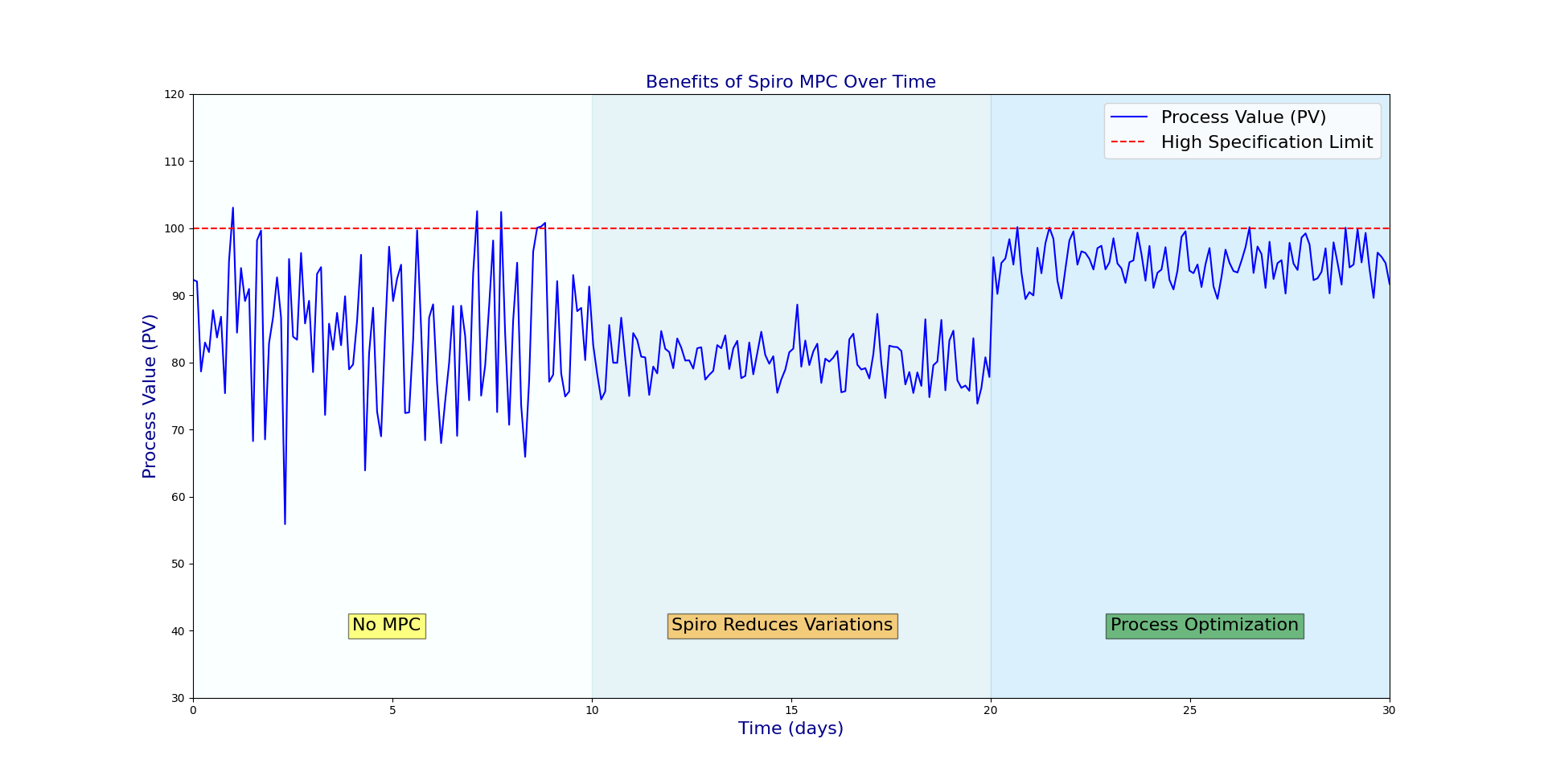

Enhanced Process Stability and Control

Spiro MPC ensures real-time optimization of production processes by continuously analyzing multiple variables and adjusting process parameters to maintain stability:

- Reduced variability in key control variables ensures greater process consistency, helping manufacturers avoid common disturbances such as feed density changes, steam pressure fluctuations, or environmental factors like temperature.

- Automated process adjustments using highly efficient algorithms increase operational stability, resulting in higher production efficiency, improved product quality, and reduced costs.

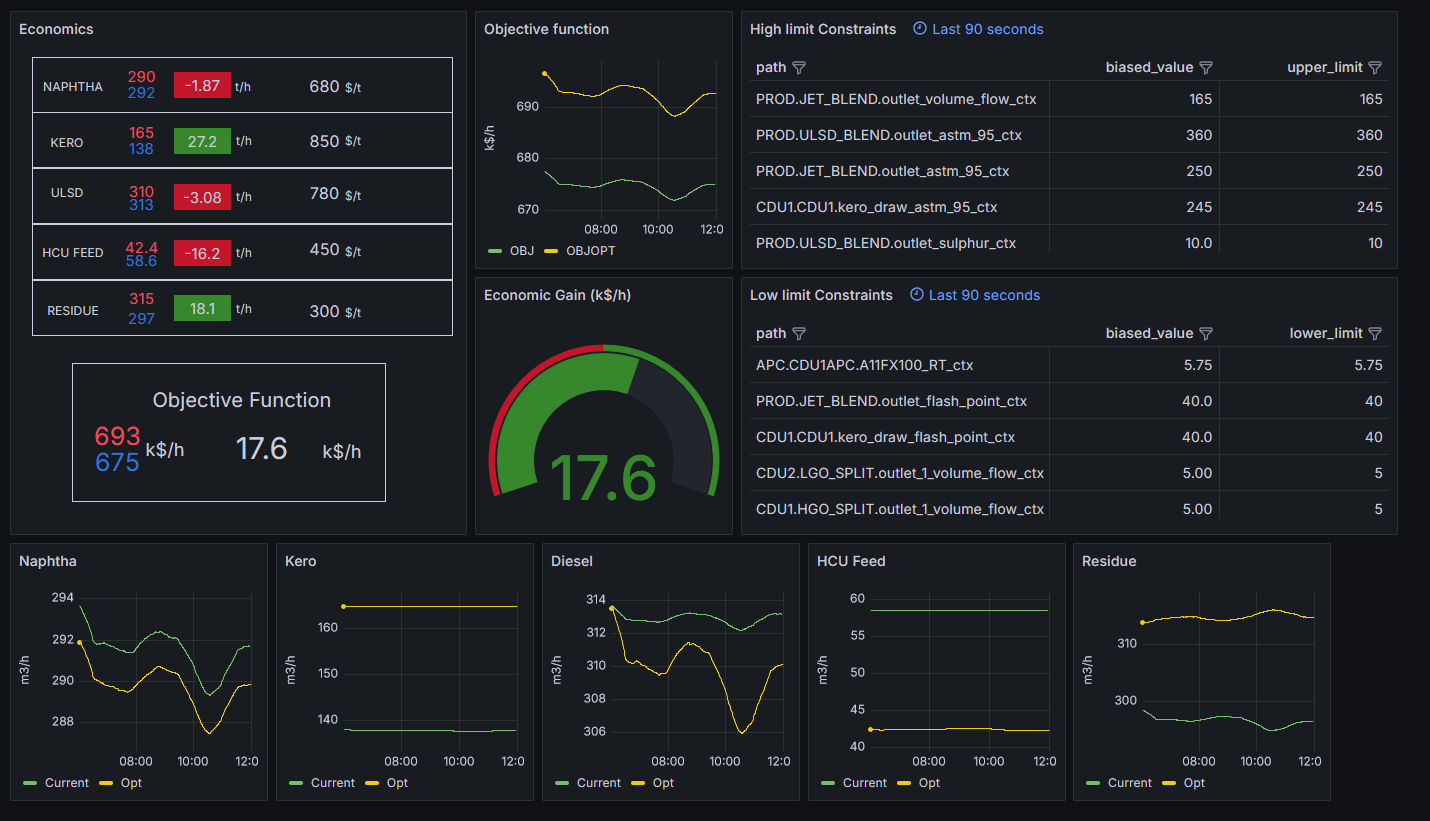

Plant-Wide Optimization

In food and beverage manufacturing, optimizing individual sub-systems is insufficient. Spiro enables a plant-wide optimization strategy:

- Cooperative distributed control ensures that each unit operates independently while maintaining alignment with overall plant objectives.

- This holistic approach optimizes the performance of all production units, enhancing overall facility efficiency and reducing resource wastage.

Real-Time Data Analytics for Operational Insights

Spiro Analytics processes and analyzes plant data in real-time, offering immediate insights into process performance:

- Edge analytics eliminates delays associated with traditional data analysis methods by analyzing data as soon as it is generated, enabling faster responses to issues such as equipment faults or production inefficiencies.

- This solution is designed to be user-friendly and accessible to control engineers on-site, providing manufacturers with actionable insights without requiring data science expertise.

Use Case – Evaporator and Spray Dryer Optimization

Evaporators and spray dryers are sensitive to disturbances such as feed density variations and changes in ambient temperature:

- Spiro MPC automatically adjusts control parameters in real-time to ensure product concentration and drying consistency, reducing deviation and ensuring repeatable production outcomes.

- By stabilizing these processes, manufacturers can improve product quality and avoid costly rework or production slowdowns.

Steam Utility Optimization

In large food and beverage plants with centralized steam utilities, energy consumption can be reduced significantly through plant-wide optimization:

- Spiro’s solution ensures efficient energy usage across reboilers, evaporators, and turbines, reducing specific energy consumption by up to 10%, which can result in annual savings of $0.2-1.6 million depending on plant size.

- The solution ensures that energy resources are allocated where needed, reducing wastage and improving overall plant efficiency.

Improved Product Quality through Predictive Control

Consistent product quality is a primary concern in the food and beverage industry. Spiro MPC leverages multivariable predictive control to:

- Reduce standard deviation in key process variables, ensuring that products maintain a consistent quality profile across production runs.

- This control system reduces the burden on human operators, allowing for automated real-time corrections that minimize human error and increase operational efficiency.

Flash Dryer Application

Adaptive MPC is applied to moisture control in a flash drying process. The system uses an adaptive model to manage the variability in feed conditions, material properties, and product specifications. It optimizes the drying process by maintaining product moisture within specification limits while maximizing throughput and minimizing energy consumption. The adaptive control model improves upon traditional PID-based systems by reacting to disturbances, reducing variability, and increasing efficiency. Over six months, the system demonstrated increased throughput, faster start-ups, and reduced product variability, with minimal maintenance requirements.

Evaporator Case Study

By automating control and managing key variables like temperature, steam flow, and product concentration, Spiro reduces process variability, energy consumption, and equipment fouling. The solution enables operators to maintain tighter control of product specifications while optimizing energy use, resulting in increased throughput, reduced operational costs, and lower environmental impact. Typical benefits include a 50% reduction in product variability, 3-10% increases in production, and up to 5% energy savings.

Spiro’s solutions, including Spiro MPC and Spiro Digital Twin, offer food and beverage manufacturers the tools necessary to optimize production processes, reduce energy consumption, and improve product quality. By leveraging real-time predictive control and edge analytics, these solutions provide immediate insights and process adjustments, enabling manufacturers to achieve operational excellence and reduce costs. With proven financial benefits and enhanced production stability, Spiro is an essential partner for food and beverage manufacturers looking to navigate the challenges of modern production environments.

Contact Us

Let us know how we can help!

Email:

info@spirocontrol.com

Or schedule a live demo

Use the calendar below to schedule a meeting with a member of our team.

Or schedule a live demo

Use the calendar below to schedule a meeting with a member of our team.

Thornton Science Park, Cheshire, CH2 4NU, UK

info@spirocontrol.com

Solutions

Products & Services

Industries

News & Updates

Company

Contact